Bahiagrass

Balm

Balsam Apple

Balsam Pear

Bamboo Shoot

Banana

Barbados Cherry

Barberry, European

Barley

Basil

Bay, Sweet

Bayberry

Bean

Bean, Adzuki

Bean, Asparagus

Bean, Broad

Bean, Chinese Long

Bean, Field

Bean, Guar

Bean, Jack

Bean, Kidney

Bean, Lablab

Bean, Lima

Bean, Moth

Bean, Mung

Bean, Navy

Bean, Pinto

Bean, Rice

Bean, Runner

Bean, Snap

Bean, Sword

Bean, Tepary

Bean, Urd

Bean, Wax

Bean, Yardlong

Bearberry

Beechnut

Beet Greens

Beet, Garden

Beet, Sugar, Conventional

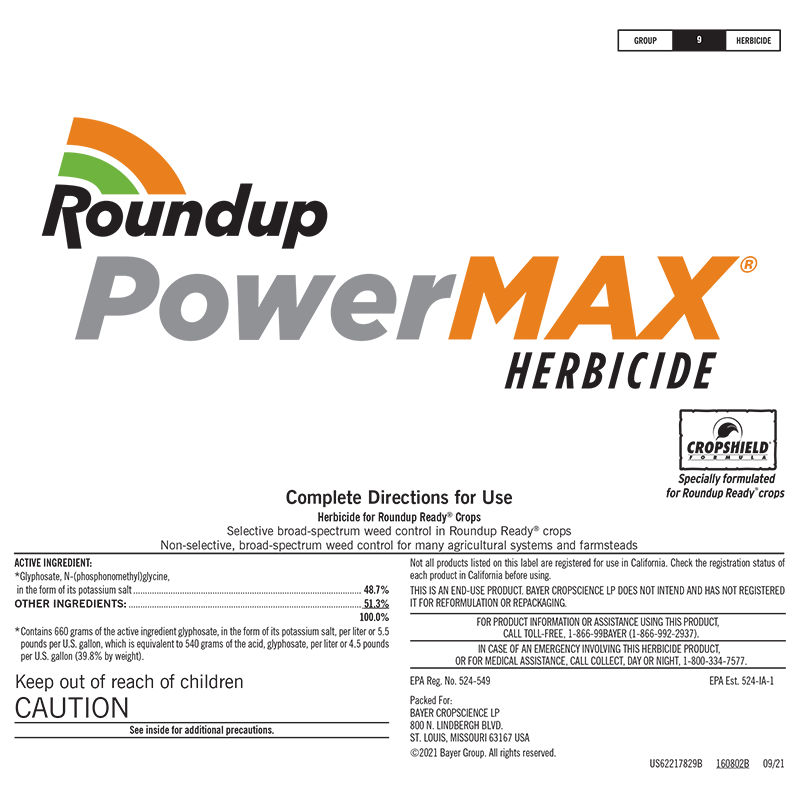

Beet, Sugar, Roundup Ready

Bermudagrass

Berry, Black Satin

Berry, Dirksen Thornless

Berry, Oregon Evergreen

Betelnut

Bilberry

Bingleberry

Biriba

Blackberry

Blackberry, Andean

Blackberry, Arctic

Blackberry, California

Blackberry, Cherokee

Blackberry, Cheyenne

Blackberry, Common

Blackberry, Evergreen

Blackberry, Mammoth

Blackberry, Shawnee

Blimbe

Blueberry

Blueberry, Highbush

Blueberry, Lowbush

Bluegrass

Borage

Boysenberry

Brazil Nut

Breadfruit

Broccoli

Broccoli, Cavalo

Broccoli, Chinese

Broccoli, Raab

Brombeere

Bromegrass

Brussels Sprout

Buckwheat

Buffaloberry

Building, Foundation

Burdock

Burnet

Butternut

Cabbage

Cabbage, Chinese Bok Choy

Cabbage, Chinese Mustard

Cabbage, Chinese Napa

Cacao

Cactus

Calabaza

Calamondin

Calendula

Canal, Dry

Canistel

Canna

Canola, Conventional

Canola, Spring, Roundup Ready

Canola, TruFlex, Roundup Ready

Canola, Winter, Roundup Ready

Cantaloupe

Caper Bud

Carambola

Caraway

Caraway, Black

Cardamom

Cardoon

Carrot

Casaba

Cashew

Cassava, Bitter

Cassava, Sweet

Cassia Bark

Cassia Bud

Castor

Catjang

Catnip

Cauliflower

Celeriac

Celery

Celery, Chinese

Celery, Seed

Celtuce

Chamomile

Chard, Swiss

Chaya

Chayote, Fruit

Chayote, Root

Che

Cherimoya

Cherry, Pin

Cherry, Sweet

Cherry, Tart

Chervil

Chervil, Dried

Chervil, Turnip-Rooted

Chesterberry

Chestnut

Chickpea

Chicory

Chinquapin

Chironja

Chive

Chive, Chinese

Chokecherry

Christmas Tree

Chrysanthemum, Edible-Leaved

Chrysanthemum, Garland

Chufa

Cinnamon

Citron

Citrus, Hybrid

Clary

Cloudberry

Clove Bud

Clover

Cocona

Coconut

Coffee

Collard

Conservation Reserve Program

Coriander, Leaf

Coriander, Seed

Corn 2, Hybrid, Roundup Ready

Corn Salad

Corn, Field

Corn, Seed

Corn, Silage

Corn, Sweet

Corn, Sweet, Roundup Ready

Coryberry

Costmary

Cotton, Conventional

Cotton, Flex, Roundup Ready

Cotton, Roundup Ready

Cowpea

Crabapple

Crambe

Cranberry

Cranberry, Highbush

Cress, Garden

Cress, Upland

Cucumber

Cucumber, Chinese

Cucuzza

Culantro, Leaf

Culantro, Seed

Cumin

Cuphea

Currant

Currant, Black

Currant, Buffalo

Currant, Native

Currant, Red

Curry, Leaf

Custard Apple