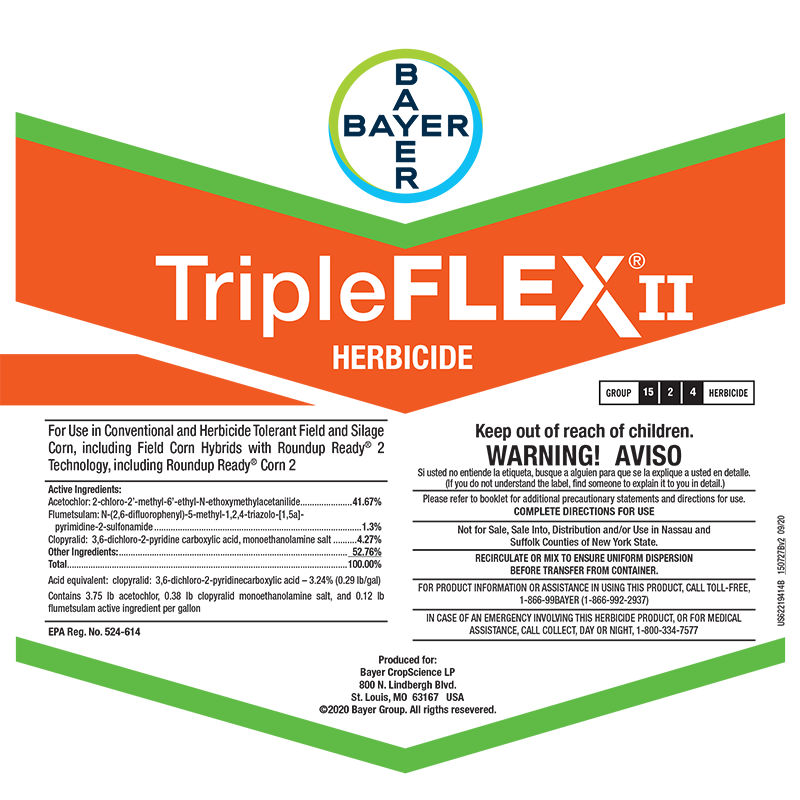

Tripleflex II Herbicide

HerbicideTripleFLEX® II herbicide is a premix of acetochlor, flumetsulam and clopyralid. This product contains three modes of action for control of weeds resistant to ALS, glyphosate or triazine. It provides broad-spectrum control of key grass and small- and large-seeded broadleaf weeds – without atrazine. With a flexible application window, TripleFLEX II can be applied preplant, pre-emergence and postemergence in corn up to 11 inches.

Approved In

AL, AR, CO, DE, GA, IA, IL, IN, KS, KY, LA, MD, MI, MN, MO, MS, NC, ND, NE, NJ, NM, NY, OH, OK, PA, SC, SD, TN, TX, VA, VT, WI, WV, WY

Labels / Safety Data Sheets (MSDS)

TRIPLEFLEX II HERBICIDE Label

TRIPLEFLEX II HERBICIDE MSDS - English

TRIPLEFLEX II HERBICIDE MSDS - Spanish

Effective Against

Our portfolio has products to fight a variety of weeds, pests and diseases.

Common Waterhemp

Crabgrass Species

Fall Panicum

Lambsquarters

Palmer Amaranth

Velvetleaf

Registered Crops

Our products are available for use on a variety of different crops.

checkcorn field

checksilage corn