Compaction in Continuous Corn

June 6, 2021

Basics of Compaction

Soils (often medium- and fine-textured soils) are vulnerable to compaction when they are at or near field capacity. Field capacity is the point at which the pore space surrounding soil particles is completely occupied with water. Water in the soil acts as a lubricant between soil aggregates. When heavy machinery puts pressure on field capacity soils, aggregates become tightly packed together.

The resulting compacted soil has fewer large pores, reduced pore volume, and increased bulk density. Plant roots growing in this environment experience aeration-related problems. Water is held instead of infiltrated through the soil profile. Soil compaction degrades land at a global level and is attributed to machinery growing heavier each decade since the 1950s.1,2

Corn Response

Emergence and Stand Counts. With conventional tillage, up to 100 percent of the field area can be trafficked during a single cropping cycle.3 Increased machinery traffic causes delays and variability in corn seedling emergence. Compaction from greater pressures per square inch, such as from road tires, has been shown to decrease corn plant population more than soils without compaction.4 Soil surface unevenness from tire-made ruts contributes to variability in seeding depth control. Uneven emergence can also be an issue with residue remaining from previous corn crops (Figure 1).

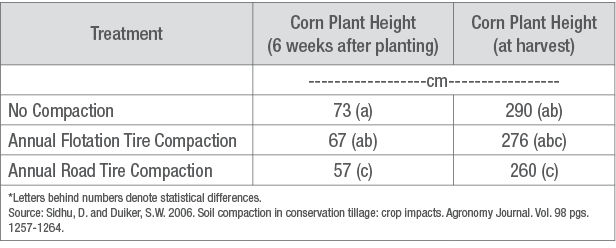

Height. Table 1 shows effects of soil compaction on corn height. Corn is a tall crop and may be more sensitive to height differences caused by compaction. At six weeks post-planting, corn had a 21 percent height advantage when grown on non-compacted soils compared to soils with annual road tire compaction. Height differences were still noticeable at harvest, and yield trends lower with plants shortened by compaction.

Ear Development and Yield Potential

Effects of compaction on ear development and yield potential are not typically consistent across fields. Corn plants are sometimes able to produce larger ears as compaction causes lower populations. However, corn can also respond by producing more ears of smaller size when grown on soils compacted by wheel traffic.4 Multiple factors affect the depth of compaction, and healthy plant development is greatly influenced by moisture stress.

Yield potential is related to ear size. A 19 to 50 percent corn yield reduction has been reported and estimated in compacted versus non-compacted soil.1,4,5 Severe subsoil compaction can occur in a single pass with a load of 20 tons per axle. Such compaction can affect corn yields for five to 12 years.4

Compaction Remedies

Freeze-Thaw versus Summer Cracking. Deep compaction naturally begins to be corrected by drying during the summer months. Soils crack as they dry, and this shrink-swell process is one way clay-type soils are alleviated of compaction. Cracks can be several feet below the soil surface. Winter freezing remedies compaction in the top few inches of soil. Several dozen freeze-thaw cycles on fields with high soil moisture (greater than 85 percent of pore space filled with water) are needed to break up compaction. Realistically, the North Central corn-growing area experiences one to two freeze-thaw cycles reaching below a six-inch depth.6

Cover Crops. Cover crops can be a better alternative to machinery implements for breaking up compaction. Cover crop root growth repairs soils by stabilizing aggregates, creating pore spaces for infiltration, and breaking through plow pans. Cover crops planted on acres with compaction issues help drain wet soils and create root channels for commodity crops to grow through. These beneficial soil services are unique to cover crop growth. Unfortunately, deep-ripping implements intended to break compaction only result in positive crop responses about 25 percent of the time.6

Compaction Prevention

Follow Tracks. Up to 80 percent of soil compaction occurs during the first pass across the field.7 Unchecked; the machinery footprint can cover the entire field. With overlaps included, a seedbed with wheel-tracks on 145 percent of the area can be created by conventional tillage.3 The change to controlled traffic pathways may take several years to achieve. Field operations become more efficient and less machine power is required with controlled field traffic. Consider the following to reduce wheel impacts:

Consider taller, narrower tires on new machinery.

Grain carts are the heaviest machinery (carrying more than 2,000 bushels) and should be the first equipment to considered in pathway control (Figure 2).4,7

Avoid diagonally crossing fields.

Properly inflate tires to reduce surface compaction. Tire pressure for field work is about one-fourth to one-third the pressure used for road conditions (45 psi).6

Eliminate tillage passes especially if the intention is to dry out fields.

Axle Loads. High axle loads combined with over-inflated tires can create ruts with double the soil compaction compared to ruts made by the same equipment with proper adjustment.6 Deep compaction (two to three feet) runs vertically and horizontally from ruts. Compaction zones can be localized to the top six to 10 inches of soil when axle loads are under 10 tons.4

Summary

Soil compaction cannot be entirely avoided but should be prevented, minimized, and controlled as much as possible. Reduction of compaction in the topsoil and subsoil creates soil with increased water infiltration and storage. The improved water/soil environment allows earlier planting dates, decreases stress on plant roots, and reduces disease potential. Tillage proposes to dry soils for these same reasons but can cause soils to weaken and have limited drainage (Figure 3). Soils are a critical resource to grow healthy, profitable crops and should be preserved for future use.

Sources

1 Eswaran, H., Lal, R., and Reich, P.F. 2001. Land degradation: an overview. United State Department of Agriculture. Natural Resources Conservation Service. https://www.nrcs.usda.gov/wps/portal/nrcs/detail/soils/use/?cid=nrcs142p2_054028.

2 Duiker, S.W. 2005. Effects of soil compaction. PennState Extension. https://extension.psu.edu/effects-of-soil-compaction/.

3 Duttmann, R., Malte, S., Nolde, M., and Horn, R. 2014. Predicting soil compaction risks related to field traffic during silage maize harvest. Soil Science Society of America Journal. Vol 78. Pgs. 408-421.

4 DeJong-Hughes, J. 2018. Soil compaction. University of Minnesota. https://extension.umn.edu/soil-management-and-health/soil-compaction#sources-1200560.

5 Khan Sial, J. 1987. Effects of controlled traffic in corn plots. Iowa State University. Digital Repository Retrospective Theses and Dissertations.

6 Daigh, A.L.M. and Bly, A. 2020. Compaction reaction: soil compaction and ruts following a wet harvest. Crops & Soils. Pgs. 24-28.

7 Gates, A. and Weir, T. 2019. 7 tips to avoid soil compaction during harvest. FarmersEdge. https://www.farmersedge.ca/7-tips-to-avoid-soil-compaction-during-harvest/.

4007_S3

Seed Brands & Traits

Crop Protection

Disclaimer

Always read and follow pesticide label directions, insect resistance management requirements (where applicable), and grain marketing and all other stewardship practices.

©2024 Bayer Group. All rights reserved.