3 MIN READ

Corn Silage Harvest Timing

August 29, 2023

- Ideal fermentation of silage requires harvest at the moisture level recommended for each type of silo.

- The kernel milk line can be used as a tool to help estimate kernel moisture content.

- Increasing cutting height can avoid dangerous nitrate concentrations in the lower parts of stalks.

- Disease can affect silage quality, and harvest priorities should shift to preserve kernel and stalk health.

Moisture for Ensiling

Corn must be ensiled at the proper moisture to achieve the necessary fermentation for preservation. It can be difficult to determine when to harvest corn at the right whole plant moisture. The optimum plant moisture for ensiling is slightly different for each type of storage structure. Harvesting corn when it is too wet (>75% plant moisture) may result in reduced yield potential, souring, and seepage. High moisture can also reduce animal performance due to reduced palatability of the silage leading to lower total feed intake. Harvesting too dry can reduce yield potential, cause mold to develop, and lower digestibility, protein, vitamin A, and vitamin E.1,2

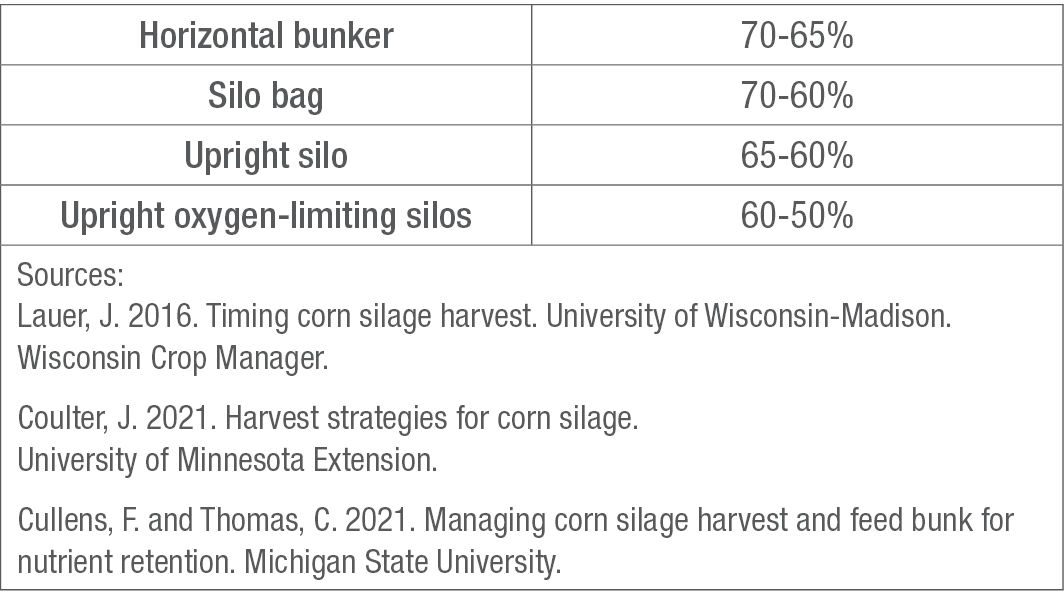

For best ensiling results, corn silage should be harvested at the moisture content appropriate for the type of silo being used.

Table 1. Moisture recommendations for ensiling storage units.

Milk Line Indication of Kernel Moisture

- To determine optimum silage harvest time, chop a sample at the full dent stage—just as the milk line appears—and measure the total plant moisture content using one of the methods described below. After measuring the total plant moisture content, estimate the harvest date by using a drydown rate of 0.50 to 0.75 percentage units per day in the month of September.1,2,3 If the weather is cool and wet, use the lower rate of drydown. If the weather is warm and dry, use the higher rate of drydown.

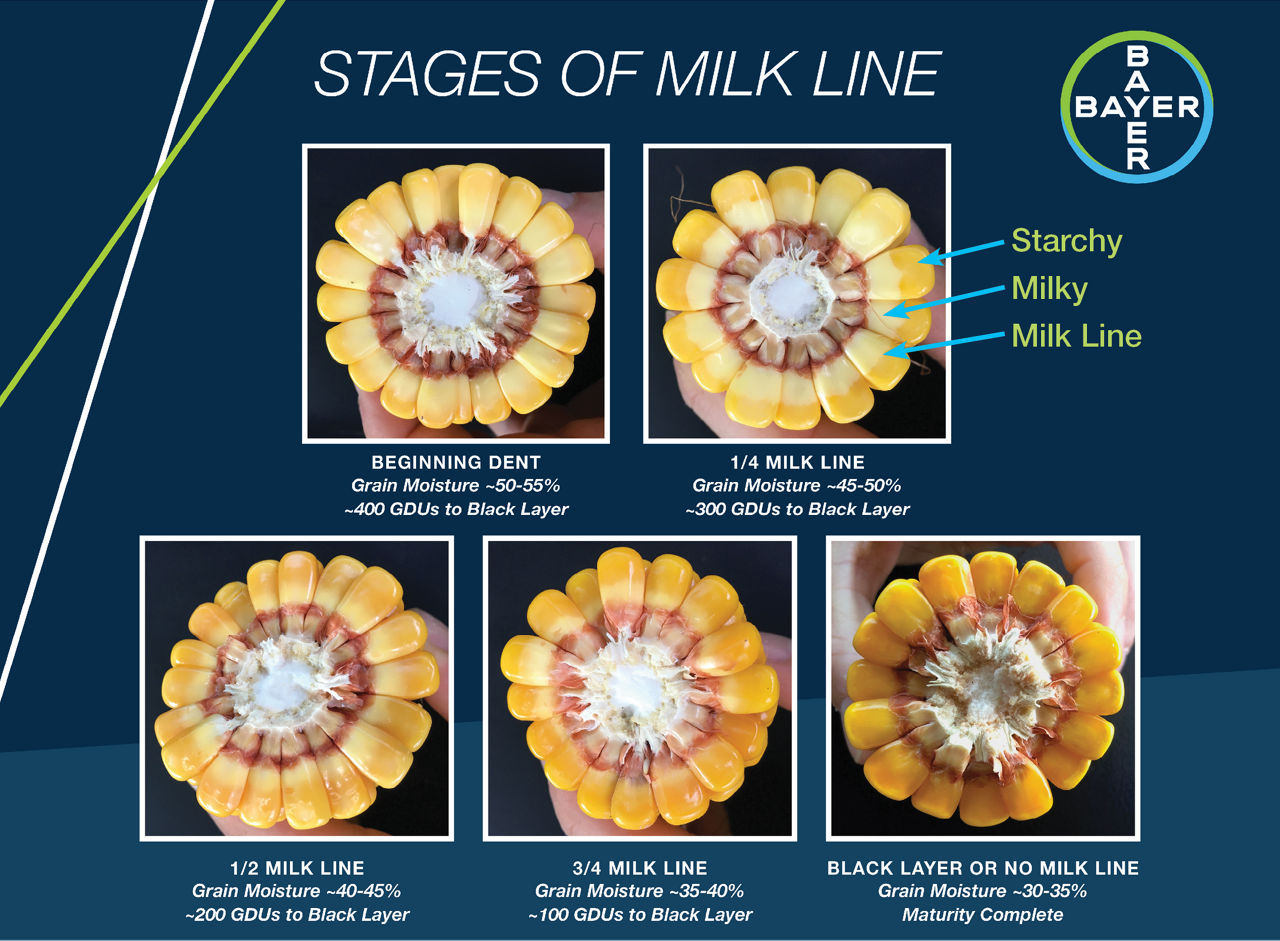

The kernel milk line growth stage is a common visual tool to estimate kernel moisture content (Figure 1). The milk line represents the starch content of the grain. Break a corn ear and observe the milk line development on the kernels. Although the milk line is not a reliable indicator of the precise total moisture, when the milk line is ½ to 2/3 down from the kernel crown, the total plant moisture content is usually between 60 to 70%.4 A microwave oven, a drying oven, or a commercial forage moisture tester can all be used to measure corn moisture content more accurately.

Harvest Height

Drought-stressed corn may have a higher-than-normal concentration of nitrate in its lower stalks. High-nitrate silage (greater than 1,000 ppm) can poison livestock, especially in lower-energy rations, and pregnant cows are particularly at risk.3,5 Rainfall increases the uptake of soil nitrogen, so harvesting drought-stressed corn should be avoided within three days of rainfall.3 Research has shown that increasing the cutting height of corn silage decreases yield potential, due to the extra stalk left in the fields. However, in some situations, higher-cut corn silage can result in greater milk production per pound of silage fed.6 Increasing the cutting height from 6 to 8 inches to 18 inches above ground level may improve silage quality, because the lowest portion of the corn stalk is typically higher in fiber and lower in digestibility.7

Plant Stress During Growing Season

Silage can be affected by plant diseases, especially those caused by fungi. Fungal diseases can cause a loss of dry matter because of leaf or stalk tissue death, resulting in poor ear fill, small kernels, and stalk lodging, which in turn results in reduced yield potential and reduced silage quality.8 In addition, certain fungal organisms can contaminate grain and stalks with mycotoxins, such as vomitoxin, causing serious quality problems. If fungicides labeled for corn silage are used, growers must pay close attention to the label for pre-harvest interval information.

Conclusion

Corn silage moisture contents increased from 58% to 63% between 2000 and 2010.4 Harvesting may need to begin when total plant moisture is at the high end of the appropriate moisture range to avoid having excessively dried kernels by the end of the harvest. Dangerous nitrate levels should be avoided by managing harvest timing and cutting height, and disease deterioration should be avoided by prioritizing the harvest of affected fields. Once silage chopping starts, exposure to oxygen should be minimized by processing quickly and packing silage.

Sources:

1 Lauer, J. 2016. Timing corn silage harvest. Integrated Pest and Crop Management. University of Wisconsin-Madison. https://ipcm.wisc.edu/blog/2016/08/timing-corn-silage-harvest/

2 Roth, G.W. and Heinrichs, J. 2001. Corn silage production and management. PennState Extension. https://extension.psu.edu/corn-silage-production-and-management

3 Coulter, J. 2021. Harvest strategies for corn silage. University of Minnesota Extension. https://extension.umn.edu/corn-harvest/harvest-strategies-corn-silage

4 Garcia, A. 2016. Corn silage production and utilization. In Clay, D.E., S.A., Clay, and E. Byamukama (Eds.) iGROW Corn. Best Management Practices. Ch. 18. South Dakota State University.

5 Drewnoski, M. 2023. Options for safely using high-nitrate forage: grazing, silage and haying. University of Nebraska – Lincoln. Options for Safely Using High-Nitrate Forage: Grazing, Silage and Haying | UNL Beef

6 Wu, Z. and Roth, G.W. 2023. Considerations in managing cutting height of corn silage. PennState Extension. https://extension.psu.edu/considerations-in-managing-cutting-height-of-corn-silage

7 Cullens, F. and Thomas, C. 2021. Managing corn silage harvest and feed bunk for nutrient retention. Michigan State University. https://www.canr.msu.edu/news/managing_corn_silage_harvest_and_feed_bunk_for_nutrient_retention

8 Isleib, J. and Chilvers, M. 2012. Diseases on corn for silage. Michigan State University. https://www.canr.msu.edu/news/diseases_on_corn_for_silage

1210_64267

You may also like...

Here are some articles that may also be of interest to you