Fungicide Application Coverage in Managing Disease

March 14, 2025

KEY POINTS

Fungicide coverage is a function of two factors:

- Spray volume (carrier)

- Droplet size (nozzle type and pressure)

These two factors are then influenced by nozzle type, ground speed, pressure, and adjuvants. These factors must be managed to achieve maximum canopy coverage and control.

Introduction

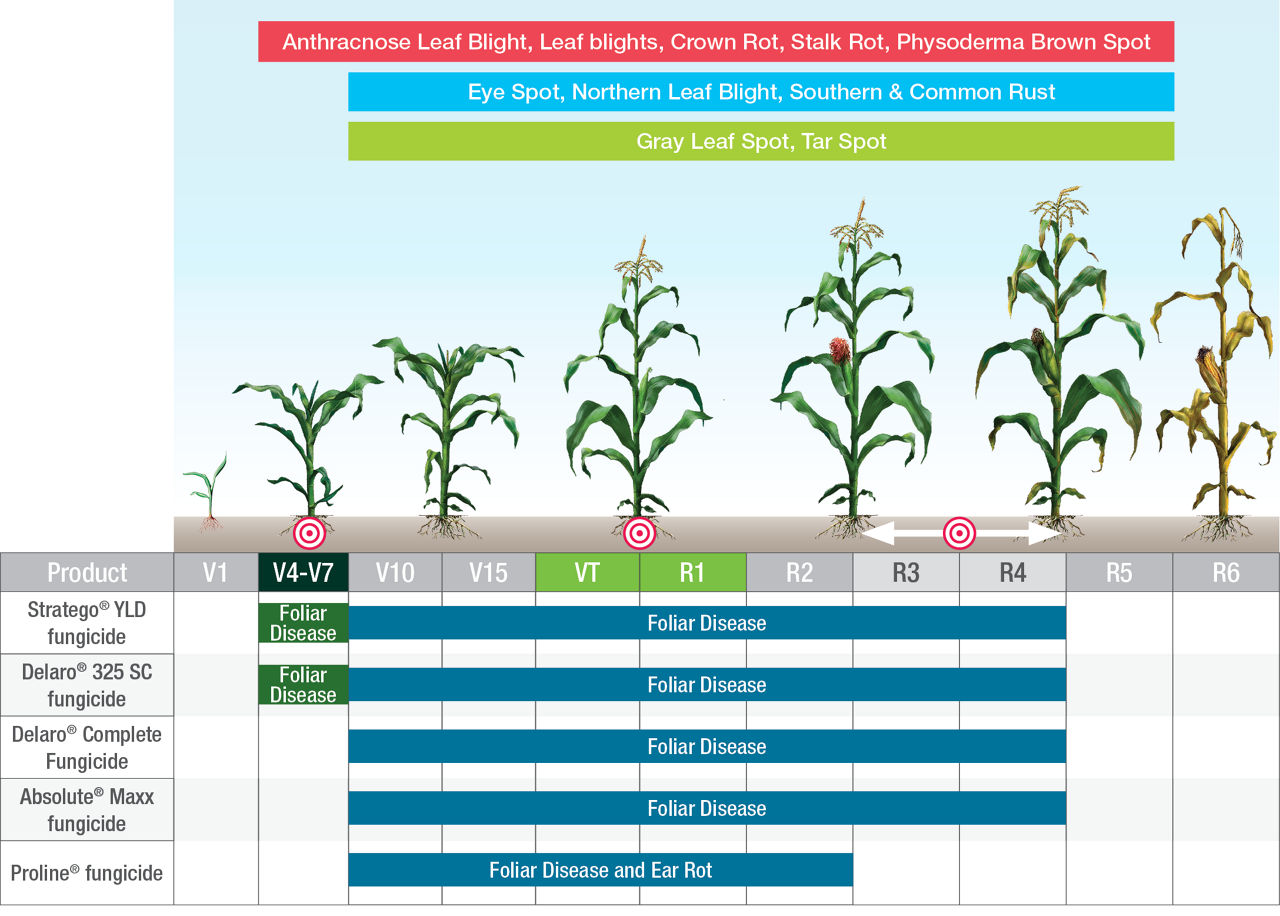

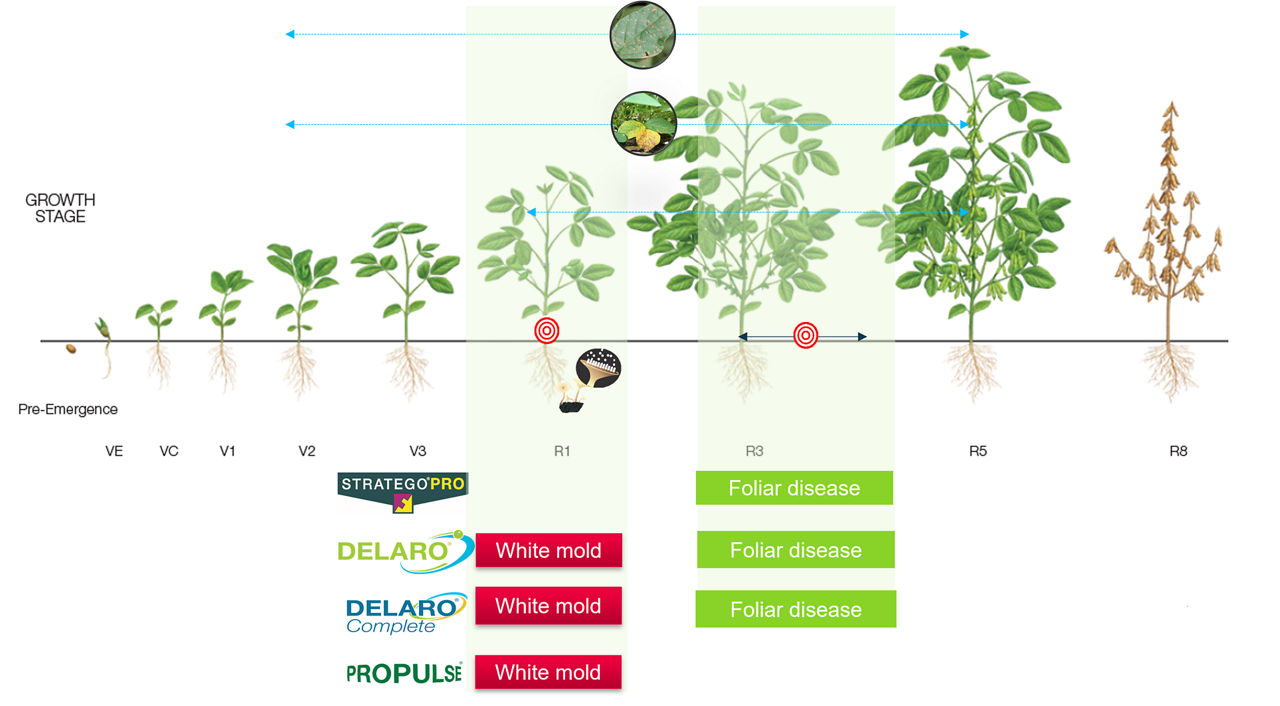

After the proper fungicide product and application timing have been determined for a given situation, growers should consider two more key factors: spray volume and droplet size. These factors are then influenced by ground speed, pressure, and adjuvants, all of which influence foliage coverage which is critical for fungicide performance. Higher carrier volumes are often needed for complete fungicide coverage, especially when treating large plants that have created a closed canopy. Many fungicides also have limited movement within the plant, which can require a higher carrier volume.

Carrier Volume

Carrier volume is affected by the type of application equipment used. Ground application equipment used for a foliar fungicide application often has a recommended carrier volume rate of between of 15 to 20 gallons (57 to 76 liters) per acre. Arial application carrier volume rates are commonly much lower, and rates of 3 to 5 gallons per acre (11 to 19 liters) are often recommended. Airplanes and helicopters once dominated as the preferred arial fungicide application equipment, but that dominance is now being challenged by drones in some markets. Drones may have an advantage over fixed wing aircraft when applying a fungicide to small fields that are surrounded by trees or other obstacles, and may have an advantage over ground application equipment when applying fungicide to tall crops, such as corn at the tassel growth stage, which most ground applicators struggle to do.

Droplet Size

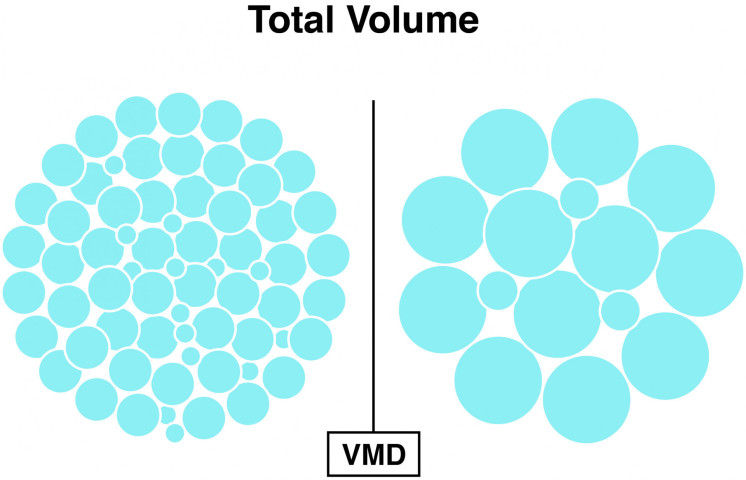

Droplet size is particularly important to consider when selecting a nozzle for a foliar fungicide application, since the nozzle affects droplet size and smaller droplets improve coverage. However, the potential for drift increases as droplet size decreases.

The American Society of Agricultural Engineers (ASABE) categorizes droplet size in agricultural applications by measuring the volume median diameter (VMD) of droplets. This measurement describes the midpoint droplet size, at which half of the volume sprayed from a nozzle is in droplets that are larger than the midpoint and half of the volume is in droplets that are smaller than the midpoint.

Nozzle manufacturers classify nozzles into seven categories by droplet size: very fine (VF), fine (F), medium (M), coarse (C), very coarse (VC), extremely coarse (XC), and ultra-coarse (UC). Several factors should be considered when determining which of the many spray pattern nozzles available is most appropriate for a given fungicide application. Application timing, crop growth stage (and thus the amount of plant foliage that will need to be covered), application method, and the specific fungal organism being managed will all influence the nozzle type suited for the application. While nozzles that produce larger droplets reduce the potential for drift, they may not provide sufficient coverage for some fungicide application. When selecting a nozzle type for a fungicide application, it is often a good starting point to select a nozzle with a fine to medium droplet for optimum plant coverage and canopy penetration. Always follow the label directions for all application requirements including type of application equipment used, nozzle recommendations, and carrier volume requirements.

Variables Affecting Application Rate

- Nozzle flow rate

- Ground speed of the sprayer

- Sprayer operating pressure

- Distance between sprayer nozzles on the boom

Nozzle Flow Rate

Increasing the flow rate of a nozzle (gallons per acre) requires an increase in the orifice hole size, assuming the ground speed and system pressure are kept the same. All manufacturer labeled flow rates are based on water as the carrier. If a carrier other than water is used, such as 28-0-0 liquid nitrogen fertilizer, then the flow rate of the nozzle will need to be recalibrated.

Ground Speed of the Sprayer

The ground speed of a fungicide application can be critical for its success. As ground speeds increase, the volume that a nozzle will be required to handle to maintain that same flow rate of carrier per acre will need to increase accordingly. For example, for a sprayer to increase the ground speed by 50%, the rate of flow out of the nozzle chosen will need to increase by 50%.

Spayer Operating Pressure

A nozzle that might be a viable choice for a fungicide application at one system pressure level may not be a correct choice for a lower or higher system pressure application, due to the change in the VMD for that nozzle at other operating system pressures. An increase in pressure will increase the flow rate of the nozzle, but this increase in flow rate is not a 1:1 increase. Doubling the flow volume of a nozzle requires a four times increase in pressure, which will drastically affect the VMD of the nozzle.

Distance Between Sprayer Nozzles on the Boom

Each nozzle is designed to operate at a specific height above the crop canopy and at a designated distance between sprayer nozzles for the correct overlap of spray coverage. Doubling the application rate can be achieved by halving the nozzle distance on the spray boom and using a nozzle with the same flow rate that was designed to be used at that reduced spacing, while maintaining the same pressure and ground speed.

Adjuvants

There are several types of adjuvants that are used to help maximize fungicide coverage and absorption into the plant. Spreader type adjuvants reduce the surface tension of droplets, which allows droplets to spread more evenly across the leaf surface. Sticker type adjuvants help keep the fungicide from washing off in the rain or during on overhead irrigation application. Drift reducing adjuvants allow for more of the active ingredient to make it to the target leaf surface. Additionally, some adjuvants help fungicides penetrant waxy leaf cuticles to help stop fungal injury. All these adjuvants can help increase the coverage or chemical activity of the fungicide, which can result in better disease control.

Advantages and Disadvantages of Several Types of Application Equipment

Each type of application equipment has advantages and disadvantages. However, as long as the correct carrier volume, pressure, adjuvants, and nozzles are used, good coverage and management can be achieved.

Ground Application

- Ground sprayer application advantages:

- Higher volume of carrier

- More precise control over spray pattern

- Better able to apply product to the specific target area

- Flexibility, as growers often have their own ground application equipment allowing timely application

- Can make applications close to obstacles around and in the field

- Ground sprayer application disadvantages:

- Dependent on soil conditions, must not be too wet for application

- May cause soil compaction if soils are too wet

- Slower speed of application

- May cause damage to crop due to crop size or tracks in the field

- In fields with uneven ground, it may be difficult to maintain consistent spray application boom height above the crop canopy

Chemigation

- Chemigation application advantages:

- Uniformity of application for best coverage and distribution, if the overhead sprinkler nozzle package is designed to give uniform foliage coverage

- Often less expensive than other application options

- Allows targeted/flexible applications

- Saves time and labor

- Reduces compaction from ground equipment

- Operator safety, reduces exposure to the applicator

- Chemigation application disadvantages

- Poorly maintained or designed irrigation systems may cause uneven applications

- Requires additional equipment to meet state law and safety requirements (see Chemigation equipment requirements, below)

- Increases wear and tear on the irrigation equipment

- Risks water source contamination

- Calibration requires skill and knowledge

The application of a fungicide through a center pivot irrigation system (chemigation) is approved for some fungicides, but only after the system has been modified to make these types of applications. Chemigation equipment requirements include the following:

- An anti-siphon device on the main water line

- Backflow device in the chemical line

- A pressure sensor on the pressurized water line

- An inspection port (to check the operation of the check valve)

- An injection port downstream from the anti-siphon device

- A chemical resistant injection pump

- Interlock between the water pump and the injection pump

Aerial Application

- Helicopter advantages

- Can apply fungicide even when fields are too wet for ground application

- Can apply to large areas in a brief time (air speed of 50 to 60 mph or 80 to 100 km/h).

- No wheel tracks

- Can make applications close to obstacles around and in the field

- Can often stop to refill the helicopter’s spray tank at the edge of the field

- Helicopter disadvantages

- Most growers do not have their own helicopter application equipment

- Less carrier is applied than with ground equipment

- Not all products have an aerial application label

- Compared to airplanes, requires more stops to refill the spay tank due to smaller sprayer tank size

- Custom aerial applicators often have less helicopter availability

- Potential increase in custom application rates compared to otherapplication types

- Airplane advantages

- Can apply fungicide even when fields are too wet for ground application

- Can apply to large areas in a brief time (application air speeds of 120 to 160 mph or 200 to 257 km/h)

- No wheel tracks

- Very efficiently applies fungicide to large fields with few obstacles

- Airplane disadvantages

- Most growers do not have their own airplane application equipment

- Less carrier is applied than with ground equipment

- Cannot get as close to obstacles in and around a field as a helicopter, drone, or ground application

- Often cannot stop to refill sprayer tank at the edge of the field

- Not all products have an aerial application label

- Drone advantages

- Can apply fungicide even when fields are too wet for ground application

- No wheel tracks

- Can make applications close to obstacles in or around the field

- Can often stop to refill the spray tank at the edge of the field

- Grower could own and operate a drone, with a drone license and a chemical applicators license, on their own property

- Can be used for spot application of fungicides

- Drone disadvantages

- Small sprayer tank that will require refilling often

- Much less carrier is applied than with ground equipment

- Not ideal for large areas given slower spraying speeds and small tank sizes, though as drone sizes increase this becomes more feasible

- Not all products have an aerial application label

- Battery may need to be changed and recharged often to keep the drone in the air

If a grower operates a drone to apply agricultural chemicals to their own crops, the drone operator must comply with these regulations and licenses:

- Approved drones must be registered with the Federal Aviation Administration

- Obtain a Part 107 license for operating the drone

- Obtain a Part 137 license for dispensing chemicals

- Obtain an exemption from certain regulations

- Obtain an aerial commercial applicator license from your state's regulatory agency

- Submit an application to the FAA that details your operations

- Demonstrate compliance with safety protocols

Drones weighing less than 55 pounds (including the weight of the substance being dispensed) may operate under 14 CFR Part 107 and require exemption from Section 107.36 Carriage of hazardous material as well as several Part 137 regulations. Drones weighing more than 55 pounds will require an exemption.2

Sources

1Mueller, D., Wise, K., and Bradley, C., et al. 2021. Foliar Fungicide. In, Fungicide Use in Field Crops Web Book. Crop Protection Network, A Product of Land Grant Universities. Doi.org/10.31274/cpn-20210329-0

2Federal Aviation Administration. 2024. Dispensing chemicals and agricultural products (Part 137) with UAS. United States Department of Transportation. https://www.faa.gov/uas/advanced_operations/dispensing_chemicals

Web sites verified 01/29/2025. 1112_500901