Managing Strip-Till Corn Using Starter Fertilizer

March 14, 2018

- Farmers applying starter fertilizer are faced with different soil conditions each year.

- Fertilizer applied in the seed furrow offers seedlings nutrients to help establish the stand before roots and leaves are fully developed.

- In many instances, strip-tilled corn with starter fertilizer has a yield advantage over conventionally tilled corn with broadcasted applications of fertilizer.

Background

Starter fertilizers have complimented broadcast applications and help mitigate reduced growth rates, lack of nutrient mobility, and decreased nutrient mineralization that may occur in cool, wet soils. Fertilizer tends to cause a positive response in corn and meets the demands of the seedling until the root system develops. Starter fertilizer placement is critical because of the salt effect on germination and early-seedling vigor. Injury from nitrogen (N) and potassium (K) is possible when a seed is in direct contact or very close proximity to the ionic forms of these nutrients.

Strip-till and no-till management are adopted for several farm management and agronomic stability considerations including reducing time, costs, fuel, and erosion as well as improving soil health. Strip-till and no-till were practiced in approximately 56 percent of corn, cotton, soybean, and wheat cropland in the United States in 2010-2011.1 Strip tillage uses a cutting coulter to create strips nearly 6 to 10 inches wide. Strips can be prepared in the fall followed by spring seeding into the strips. In addition to saving inputs, strip-till favors corn root development and absorption of water and nutrients.

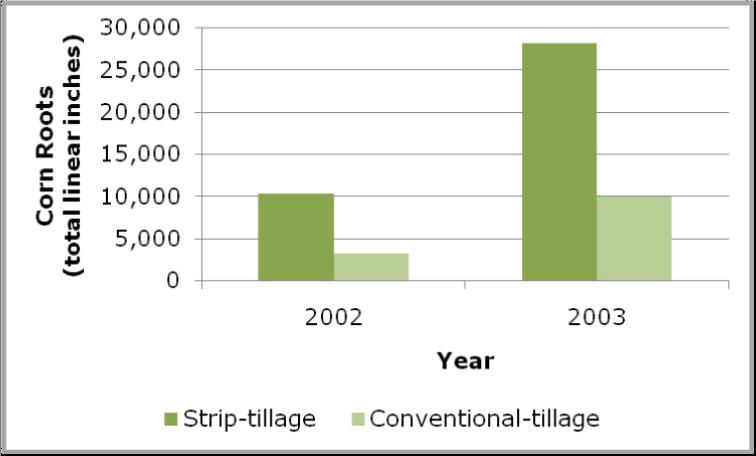

A seven-year study in two Kansas locations measured corn roots in strip till and conventional-till management.2 Root digs during the extremely dry years of the study (2002 to 2003) compared root length in strip-till and conventional till management (Figure 1). Extra root length was observed for the strip-till plot and could be the result of improved soil structure: preservation of soil colloids, root channels from other crops, and soil pores. This extension of root length meant plants could readily retrieve nutrients and moisture from the soil as roots grew down into the soil profile. The positive response in corn yield was likely the result of plants being able to access additional moisture and nutrients deeper in the soil. Strip-till management can benefit crop root health; consequently, plants may develop the root structure necessary to support greater grain yield.

Starter Fertilizer Rate and Placement

Starter fertilizer applications to fields with heavy residue, early plantings, and conservation tillage may improve emergence and early growth when soils are cool and when N is tied up in microbes breaking down residue.

Rate and Placement. Soil tests should guide fertilizer rates and samples taken from two depths: 1) the top four inches and 2) the four to 12-inch depth. These depths guide nutrient placement as strip-tillers can apply fertilizer in both depths at planting and avoid salt effects from N and K2O fertilizer placed with the seed. In addition to seed protection, fertilizer in both depths encourages root and above-ground growth. University guidelines generally limit the total amount of N and K in the form of K2O placed with or near seeds:

- In direct contact with the seed. Up to five pounds N+K2O/acre for sandy soils and up to 10 pounds N+K2O/acre for clayey soils in 30-inch rows.3

- Two inches horizontally and two inches deeper (2x2) than theseed. The combined rate of N+K2O should not exceed 100 pounds/acre.4

Equipment. Compared to broadcasted fertilizer, fertilizer rates are more concentrated and can be reduced in strip-tilled fields.5 However, reduced rates mean nutrient placement should be precise and equipment settings calibrated for accurate metering. Advances in strip-till have encouraged farmers to customize equipment to handle a variety of conditions. Some equipment considerations to benefit planting and fertilizing strip-till fields include:

- Fertilizer placement tubes can be raised or lowered behind mole knives on the strip-till rig.

- Anhydrous shanks can be added if UAN or anhydrous liquid fertilizers are favored due to soil type, weather conditions, and soil sample results.

- Strip-till planting equipment may have a 'freshener' attachment which may be arranged as blades preceding a rolling basket. A strip-freshener operation mixes the top two inches of soil to condition fall-made berms after a long winter or wet spring.

- Fertilizers formulated as suspensions can be used if N, P, K soil tests recommend more K than is safe to put with seed. A piston pump and hydraulic drive should be added on the rig to apply suspension fertilizers.

In addition to precise fertilizer placement, farmers need to accurately plant seeds in the middle of berms and above the fertilizer band to optimize corn yield potential. Corn yield can be optimized when kernels are placed in the middle of berms. According to 2010-11 Minnesota research, three out of four replications had a 5.5 percent yield increase when the seed was planted in the middle of the berm compared to the edge.6 This difference is related to temperature and distance from the fertilizer band.

Sources:

1Wade, T., Claassen, R., and Wallander, S. 2015. Conservation-practice adoption rates vary widely by region. USDA. Economic Research Service.

2Corn production and strip-tillage in the Western Plains. 2011. Monsanto National Research Summary.

3Warncke, D. 2007. Fertilizer placement. Michigan State University. http://news.msue.msu.edu .

4Steinke, K. 2013. Look beyond product rates when considering pop-up fertilizers. Michigan State University.

5Zemlicka, J. 2014. Banding vs. broadcasting: saving fuel, fertilizer with strip-till. Farm Journal's AgPro. http://www.agprofessional.com/strip-tillage/nutrient-placement/banding-vsbroadcast- saving-fuel-fertilizer-strip-till.

6Zinkand, D. 'Work the zone' to boost strip-till fertility. Strip-Till Farmer. Hitting the Sweet Spot with Strip-Till Fertilization Practices. p. 16.

Web sources verified 5/1/2017 ID 170421064838