Fertility from a Manure Perspective

January 28, 2024

KEY POINTS

- Manure can be an excellent source of nitrogen, phosphorus, and potassium for crop production.

- Broadcasting, injection, and irrigation are the primary methods for manure application.

- Manure Management Plans are necessary for operations that apply manure to agricultural land.

Introduction

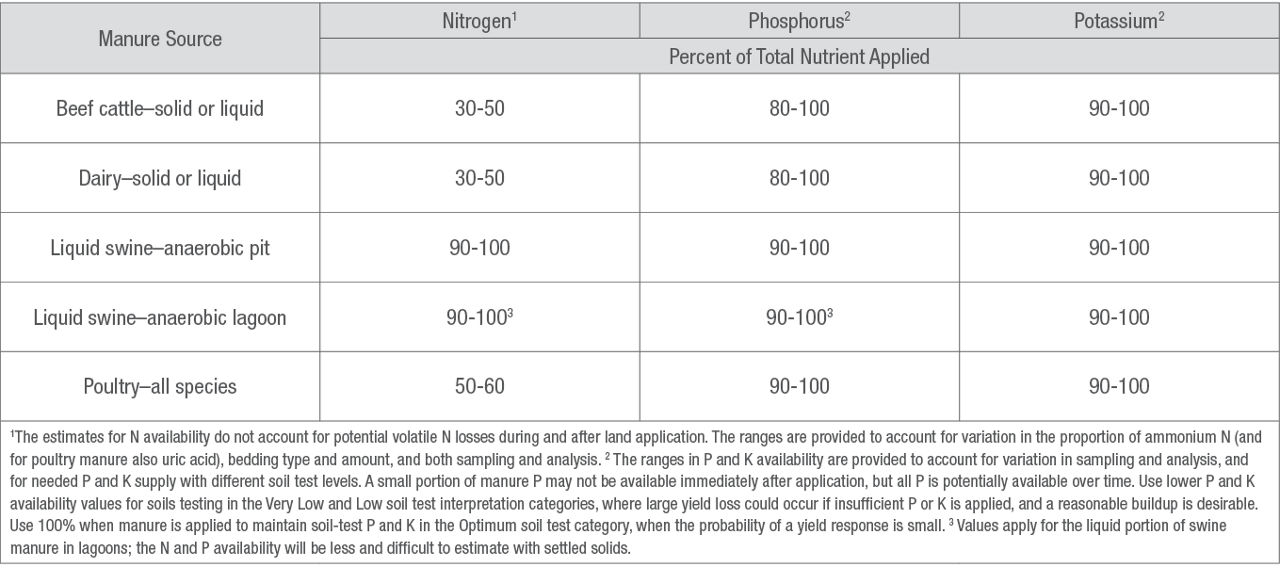

Nitrogen (N), phosphorus (P), and potassium (K) are among the many nutrients that can be returned to the soil with a manure application. Manure can help nourish growing crops, rebuild soil nutrient levels, and gradually increase soil organic matter. This can be especially important in silage fields where nutrient removal is coupled with plant tissue removal. Silage production is often located close to livestock operations, where a manure source is available, so a manure application to a silage field after harvest is often a good option. Manure can be difficult to manage as a fertilizer because it can contain organic and inorganic material, be variable in nutrient concentrations from different and within animal species, vary from sample-to-sample, be in liquid or dry forms, and in some situations be low in nutrient concentrations, which can require large application volumes. Additionally, nutrients such as N and P within manure can be tied up until microorganisms release (mineralize) these nutrients from fibrous feed or bedding components and make them available for plant growth. Potassium in manure is readily available for crop uptake (Table 1).1

Table 1. First-year nutrient availability for different animal manure sources.

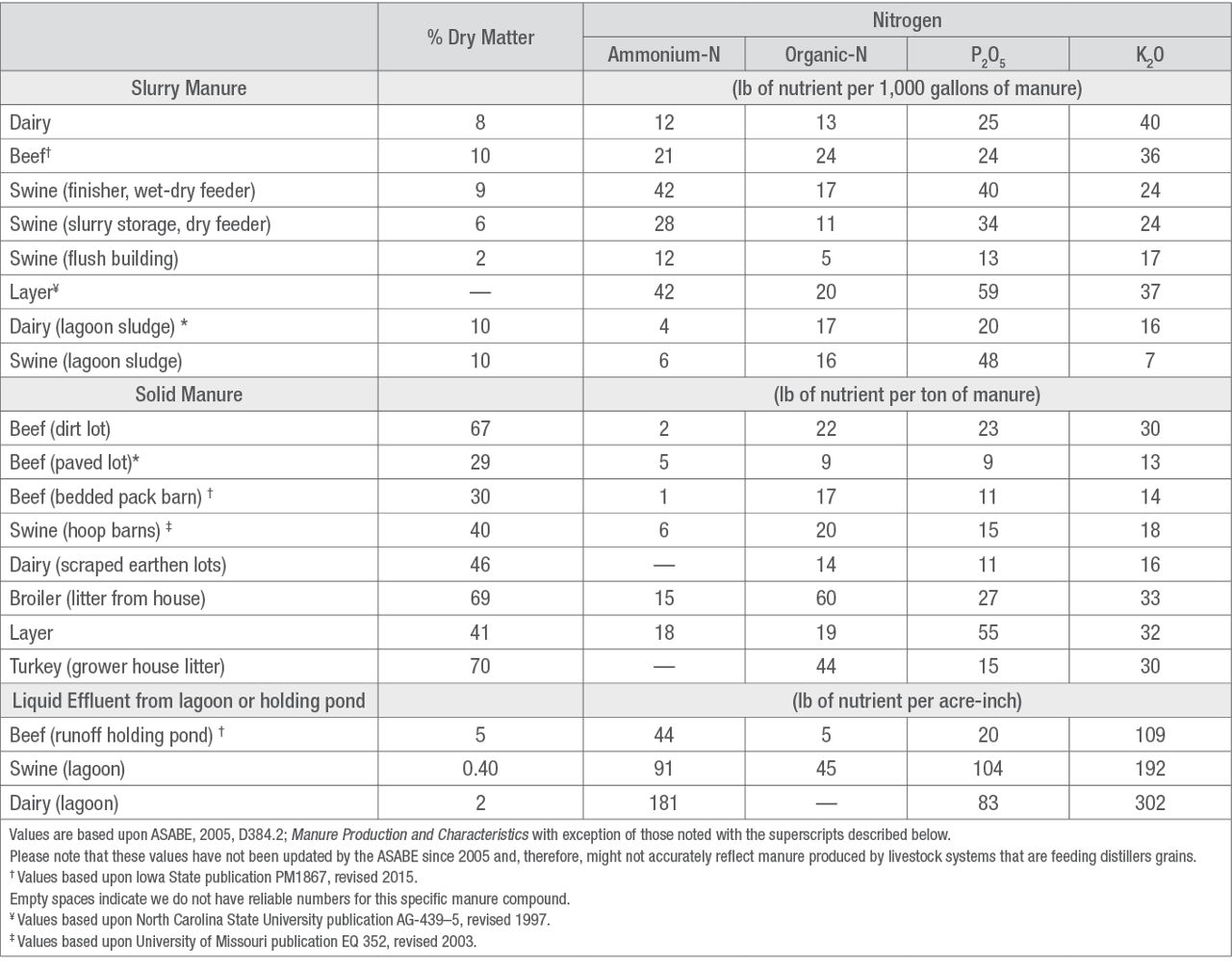

Nutrient content within manure can vary greatly because of animal species, manure moisture, diet, genetics and performance, bedding used, storage, handling, lagoon agitation, and other management factors (Table 2).2

Table 2. Manure nutrient level estimates. Individual manure analysis is preferable to estimates due to variability between farms.

Manure Attributes

Manure samples should be sent to qualified laboratories to determine the total N, P2O5, and K2O concentrations. Manure application rates are easier to calculate if the analysis is provided on an as-received or wet-basis in lb/ton or lb/1000 gal units. Conversion factors must be used if the analysis is not in these units. If manure applications are made prior to receiving the laboratory analysis, standard estimations for the manure source can be used (Table 2).2 The variation in nutrient concentrations should be noted between and within animal species. Knowing the analysis is also important for environmental reasons. Applying too much of a nutrient that can change and/or move by denitrification, volatilization, leaching, or erosion can result in ground and surface water contamination. When manure is not incorporated, N can be lost through volatilization and if applied in the fall, the opportunity for leaching increases. Phosphorus can be lost when flooding carries the manure off the target field and into creeks and other waterways.

Methods for Manure Application

Broadcast, injection, and irrigation are the most often used methods for manure application. Benefits of broadcast applications include speed of delivery and wider application widths, when compared to injection. Broadcasting may reach widths of 50 feet while injection systems are much narrower and requires more time to apply. However, without immediate incorporation, broadcast manure can be subject to loss of N through volatilization, loss of P through surface runoff, and complaints by neighbors from odor. If wintertime broadcast (Figure 1) manure application is unavoidable:

- Maintain 100-foot setback from streams, lakes, ponds, drinking water wells, and aboveground inlets to agricultural drainage systems.

- Do not spread on slopes of greater than 15%.

- Limit application rates to less than 5,000 gallons/acre liquid, 20 tons/acre of solid non-poultry /acre dry manure, or three tons of solid poultry manure.

- Avoid applying to fields with less than 25% residue cover unless a cover crop is planted. 3

Injection and irrigation of liquid manure can help control application variability, provide a better method of matching application timing to the nutrient need of the crop, and help mitigate potential environmental issues.

The injection method allows for application to growing crops such as alfalfa, grass, cover crops, and used as a sidedress in corn. Injection systems are compatible with no-till management. However, labor and equipment costs for injectable systems can be high; therefore, several factors should be considered before investing in injection equipment:

- Amount of manure produced by an operation.

- Number of hours the equipment will be used.

- Need for nurse trucks, draglines, and other associated equipment.

Liquid and solid manure (when possible) should be placed (injected) three to six inches below the soil surface. The five primary application tools for injection that disturb soil the least, are disk injection, chisel injection, high-pressure injection, aeration, and surface banding for shallow injection in standing forages.4 Aeration systems create holes in the soil that allows later surface applied manure to seep into the soil. Regardless of the potential benefits of injection systems, many still prefer broadcasting manure because of the speed of application. If the manure injection equipment is too expensive for an individual livestock producer, consider custom applicator options for that application.

There are many different types of irrigation systems used for liquid manure application. Hand-move, stationary big gun, traveling big gun, wheel lines and center pivot irrigation are some of the most popular systems used for liquid manure application. Each has its advantages and disadvantages depending on the amount of manure that will be applied by a system, the amount of screening and solid separation needed to keep each type of system free from plugging during application, and the labor requirement needed for operation. Benefits of using irrigation systems to distribute liquid manure include:

- Lower distribution costs for producers and reduced risk of spills when compared to manure haulers/tankers.

- Reduced traffic limiting soil compaction and potential damage to roadways.

- Ability to apply during the growing season when the crop has the greatest nutrient demand.

- Potential for less risk of surface runoff if managed properly.

- Potential for less nutrient leaching because plants can start accessing the nutrients soon after application.5

Health concerns regarding small particulate drift have been expressed when irrigation is used to apply liquid manure. Concerns include toxins, pathogens, odor spikes, air quality, and surface and groundwater contamination.5 Additionally, application sites are typically limited to fields that are located near lagoons due to the expense to pipe liquid manure to the irrigation systems. It is very important to screen out the solids that have the potential to plug the sprinkler nozzles used to apply the liquid manure. The nutrient concentration (NH3) and salt concentration levels of liquid manure should be closely monitored because manure with an electrical conductivity (EC) greater than 6 mmho/cm can damage corn and soybeans if applied before the eight-leaf growth stage for corn and the V3 growth stage for soybeans. Extremely high EC ratings manure, above 12 mmho/cm, can kill small and emerging plants. This concern can be managed if the liquid manure is diluted with fresh water to keep the EC below 6 mmho/cm.6 These issues and others should be evaluated for the local area before irrigation equipment is purchased for the sole benefit of manure distribution or retrofitting existing irrigation systems for this type of manure application. Always follow local regulations to determine the equipment needed to comply with the use of irrigation equipment for a liquid manure application.

Dry Manure Composting

Benefits of composting dry animal manure:

- Odor reduction.

- Parasite, pathogen, and fly egg reduction.

- Lower weed seed viability.

- Reduces the volume that will need to be hauled by 50 to 65%.

- Increases the nutrient concentration of the manure.

- Reduces the potential to pollute.7

Many of the challenges for a dry manure application can be mitigated through composting. The composting process takes time, an area dedicated to the composting process, management, equipment, and labor. Composting a mixture of organic residues like manure and bedding and even animal carcasses can result in a uniform, nutrient dense, low odor source of fertilizer for crops.

Composting is more than just piling the manure and waiting to apply it later. Composting requires routine mixing that adds oxygen to the manure which stimulates aerobic microorganisms. Under dry conditions it may be necessary to add water or liquid manure to keep the microorganisms active. The mixing process is necessary to keep the compost pile at a temperature of 113 to 160 °F which pushes the composting process forward. The time needed for composting to reduce the viability of weed seeds varies by weed species, but 42 days has shown to reduce the viability of most weed species.7

Manure Management Plan (MMP)

With any manure production or application to a field-crop or pasture, there is a concern for the potential risk of environmental impact and contamination from manure storage, application, or spill if it is not managed properly. This is why all farms, facilities, or properties that apply manure to crop fields and pastures or that have manure-producing animals must have a written MMP. A written MMP is needed for any farming operations that has an Animal Concentration Area (ACA) or pasture. In addition, all farming operations that land-apply manure or agricultural process wastewater, whether they generate the manure or import it from another operation, must also have a written MMP.8 This plan can be written by the livestock farmer, farmer, or by a certified nutrient management specialist but must be kept on the farmstead and available upon request. Different sized animal operations will have different designations and different regulations and requirements that will need to be followed. Larger animal feeding operations (AFOs) are defined as an agricultural business or operations where the animals are raised in confined situations for at least 45 days per year. Concentrated Animal Feeding Operations (CAFOs) are defined as an intensive animal feeding operation in which over 1,000 animal units are confined for over 45 days a year. An animal unit is the equivalent of 1,000 pounds of "live" animal weight. Any size AFO that discharges any manure or wastewater into a ditch, stream, or any other waterway regardless of size is considered a CAFO. Concentrated Animal Operations (CAOs) are defined as an agricultural operation where the animal density of all livestock on the farm exceeds eight or more animal equivalent units (AEUs) with an animal density of two AEU per acre on an annualized basis.9 An AEU is one thousand pounds live weight of livestock or poultry animals, on an annualized basis, regardless of the actual number of individual animals comprising the unit. CAFOs and CAOs must have a more detailed written manure plan known as a Nutrient Management Plan (NMP), which focuses on nutrient management and will need to be prepared by Certified Nutrient Management Specialists. These NMPs are submitted to local county conservation districts for review and approval. The NMP offers guidance for:

- Manure testing.

- Application equipment calibration.

- Estimating nutrient availability.

- Manure application rate.

- Other specific nutrient managements factors that may be required by the state.

The components of an MMP include:

- Operation information.

- Mechanical Manure Application.

- Farm maps.

- Record keeping.

- Manure storage, stockpiling and stacking areas.

- Pasture management (owned or rented).

- Animal Concentration Areas (ACAs) (owned or rented).

While many of the components for a MMP are consistent from state-to-state there are different state specific regulations. The National Pollutant Discharge Elimination System (NPDES) program provides the federal foundation for the MMPs, but there are many local differences due to climate and soil changes that can impact manure nutrient management. These differences include state specific programs, policies, and tools to help comply with state differences. Along with these different programs are specialized tools and training to help manage state specific regulations and permitting. Consult your local state land grant university for regulations concerning an MMP specific for your area.

Balancing Crop Nutrient Removal and Availability

Practicing good soil fertility stewardship is the premise of the 4Rs of nutrient management--applying the right fertilizer source, at the right rate, at the right time, and in the right place.10 The first step in determining the correct manure application rate is to measure the current nutrient levels of a manure targeted field through assays of comprehensive and representative soil samples. It is also important to know the field history of any manure applications over the previous couple of years. This is important because there can be N credits from the organic N in the manure that can be released from previous applications. Nitrogen credits vary and lower each year until that credit reaches zero after the third year. The desired manure application rate for each field is based on the projected crop yield, the nutrient removal for a specific crop, and the current fertility in the soil as determined by soil analysis. The available N content is calculated as 60% of the organic-N and 80% of the NH4+ (depending on the manure source), for the first year after manure application if the manure is incorporated immediately. If the manure is not immediately incorporated, then the NH4+ component should be reduced by 15% per day for each day the manure is not incorporated.11 Any NH4 that is applied and incorporated into the soil, before the soil temperature has dropped to 50°F, can be converted by the soil into NO3-, which is at risk for loss by leaching before the crop can take it up. The NH4+ is very stable in the soil and is resistant to leaching, while NO3- is easily leachable by water movement through the soil, especially in light or sandy soil types. This is why it is advantageous to apply manure after the soil has cooled to below 50 °F. In many situations, additional fertilizer may need to be added to the field to compensate for nutrients that are lacking in the manure. In addition, any potential nutrient loss when manure is applied to the soil surface must be accounted for.

Manure application timing and placement can impact the rate. Fall and surface-applied manure applications have greater opportunities for loss. Applying manure during drought conditions has advantages and disadvantages. Applying manure during a drought can allow for an earlier application window in the fall, with less potential for any manure N to be converted to nitrate (NO3-) or leached away. However, injecting manure during a drought can make it more difficult to run an injection chisel knife through the soil, which can require a higher horsepower tractor to run the same size application equipment, increasing the cost per acre for that application operation. Spring applications can be challenging due to the potential for extended wet weather causing delays or volatilization. Additionally, the workload during the spring is already busy with preparing fields for planting. Summer manure applications can be limited to crop rotations that allow for the crop to be harvested during the summer months prior to an application and to irrigation applied liquid manure that allows for application while there is a crop growing in the field.

Sources:

1 Sawyer, J.E., and Mallarino, A.P. 2016. Using manure nutrients for crop production. PMR 1003. Iowa State University. Extension and Outreach. https://store.extension.iastate.edu/product/Using-Manure-Nutrients-for-Crop-Production.

2 Shapiro, C.A., Johnson, L., Millmier Schmidt, A., Richard, K.K., and Iqbal, J. 2021. Determining crop available nutrients from manure. University of Nebraska Lincoln. Nebraska Extension G1335 https://extensionpublications.unl.edu/assets/html/g1335/build/g1335.htm.

3 White, C. and Meinen, R. 2022. The do's and don'ts of winter manure spreading. Pennsylvania State University. PennState Extension.https://extension.psu.edu/the-dos-and-donts-of-winter-manure-spreading.

4 Maguire, R., Beegle, D., McGrath, J., and Ketterongs, Q.M. 2023. Manure injection in no-till and pasture systems. Virginia Tech and Virginia State University. Virginia Cooperative Extension. Publication CSES-22P. https://digitalpubs.ext.vt.edu/vcedigitalpubs/5983297597286735/MobilePagedReplica.action?pm=1&folio=1#pg1.

5 Austin, J., Yost, M., Miller, R., Allen, N., Larsen, R., Creech, E., and Cardon, G. 2021. Manure application through pressurized irrigation systems. Utah State University. Utah State University Extension Crops. https://extension.usu.edu/crops/research/manure-application-through-pressurized-irrigation-systems.

6 Kranz, W.L., Koelsch, R.K., and, Shapiro, C.A. 2007. Application of liquid animal manure using center pivot irrigation systems. University of Nebraska Lincoln. Nebraska Extension Publications EC778. https://extensionpubs.unl.edu/publication/9000016364607/application-of-liquid-animal-manures-using-center-pivot-irrigation-systems/.

7 Keena, M.A. 2022. Composting animal manures: A guide to the process and management of animal manure compost. North Dakota State University. Ag Home, Extension, publication. https://www.ndsu.edu/agriculture/extension/publications/composting-animal-manures-guide-process-and-management-animal-manure-compost.

8 2022. The basics of manure management requirements. Pennsylvania State University. Penn State Extension. https://extension.psu.edu/programs/nutrient-management/manure/overview-of-deps-manure-management-manual/the-basics-of-manure-management-requirements#:~:text=Manure%20Management%20Plans%20identify%20manure,and%20requirements%20for%20winter%20application.

9 Environmental health: Concentrated animal feeding operations (CAFOs). Wisconsin Department of Health Services. https://www.dhs.wisconsin.gov/environmental/cafo.htm#:~:text=Concentrated%20Animal%20Feeding%20Operations%20(CAFOs)%20are%20agricultural%20meat%2C%20dairy,lands%2C%20animals%20are%20given%20food.

10 What are the 4Rs. The Fertilizer Institute. 4 Rs nutrient stewardship. https://nutrientstewardship.org/4rs/.

11 Camberato, J.J. 1996. Land application of animal manure. Clemson University. Clemson Extension. EC 673. https://www.mssoy.org/uploads/files/clemson-analysis.PDF.

Web sources verified 11/15/23. 1013_321459

Seed Brands & Traits

Crop Protection

Disclaimer

Always read and follow pesticide label directions, insect resistance management requirements (where applicable), and grain marketing and all other stewardship practices.

©2024 Bayer Group. All rights reserved.