Grain Quality Series Part 2: Limiting Foreign Materials and Dockage in Wheat

February 4, 2020

If you grow wheat, you know grain quality is a focus and is critical to producing a healthy bottom line. But key contributors like grain damage, foreign materials, vomitoxin, test weight and moisture all play important parts in determining year-end profits.

In this second installment of our five-part “Grain Quality” series, we discuss how foreign materials and dockage levels impact grain grading and how it can count against your bottom line at the elevator. We also discuss how Fusarium head blight (FHB) and its byproduct deoxynivalenol (DON), or vomitoxin, can impact profits and what you can do to lower risk from the disease.

In case you missed the first part of this series on grain quality, please refer to our in-depth analysis on limiting grain damage.

Foreign Materials and Dockage

Foreign material and dockage can impact your bottom line, so it’s important to know the causative factors to their presence in your grain.

The percentages of foreign materials and dockage can be direct indicators of problems that typically occur in the field, before harvest begins. Factors such as disease and weed pressure are key contributors and as these levels rise, they can negatively affect the price of your grain.

Inputs Matter

Jochum Wiersma, associate professor and extension agronomist at the University of Minnesota, says that growers should use the best inputs that limit weed and disease pressure consistently to limit foreign materials and dockage levels.

“Wheat growing requires significant planning and commitment to minimize loss,” said Wiersma. “If inputs make sense based on field conditions, go ahead and use them. You cannot take every input away with slim margins if they will help increase bushels per acre.”

Kevin Thorsness, technical service representative at Bayer, agrees adding that growers should have a solid weed-management program in place.

“Weed control in cereal production should consist of starting clean with either a tillage operation or a burndown application of a Roundup® Brand Agricultural Herbicide,” said Thorsness. “Post-emergence herbicides, such as Luxxur™ herbicide or Huskie® Complete herbicide, should be applied early in the growing season to maximize control of the target weeds.”

Luxxur herbicide is a new herbicide from Bayer that can help growers control a wide spectrum of grass and broadleaf weeds, including wild oats, dandelions, Canada thistle, green foxtail, yellow foxtail and narrow-leaved hawksbeard. It has been specifically formulated to allow growers to rotate to a wide variety of crops the following season, including sugar beets, peas, lentils, chickpeas and more.

Alternatively, flexible applications of a tough herbicide product like Huskie® Complete is another solid strategy for controlling weeds, including marestail and kochia.

Overall, managing weeds is important for maximizing yield and quality in cereals production. However, it is also important to have an effective disease management program in place as well.

FHB and Vomitoxin

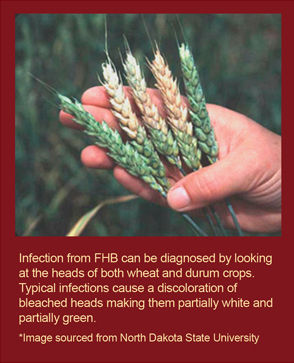

Diseases can colonize head and leaf tissue, resulting in reduced yields and damaged, shriveled kernels. All of which can affect dockage levels at harvest. One common disease that leads to dockage at harvest is Fusarium head blight (FHB). Infection can result in crop-quality issues like shrunken kernels, yield reductions and lighter test weights.

FHB can result in the production of a mycotoxin called deoxynivalenol (DON), or vomitoxin. Mycotoxins, like DON, affect grain quality and can make it unacceptable for certain end-use production, thus demanding lower prices on the open market. These quality reductions can also result from fungal mycotoxins produced during an infection.

According to North Dakota State University, vomitoxin is the most common mycotoxin to affect wheat. Heavily contaminated grain is usually unfit for human consumption and can be discounted or completely turned away at market.1

Making matters worse, FHB can exist in a field for quite some time without clear symptoms during routine scouting. This makes handling FHB and DON difficult for many growers. Fortunately, growers can proactively reduce risk from DON and maintain high-quality grain.

Proactivity Proves Best

A proactive and preventive approach to vomitoxin is the best way to limit losses. Planning is the key to managing FHB and vomitoxin.

There will always be a risk of FHB on winter and spring wheat. To limit risk, growers need to have an effective plan in place. Carefully choosing varieties that provide the highest possible yields and strongest resistance to FHB is a great place to start.

Growers should also examine their crop rotations to minimize overwintering of FHB in crop residue. Planting wheat is better following crops that don’t play host to the disease like sunflowers, soybeans or peas. Yet, planting wheat after corn is risky because it holds a much higher level of FHB.

In addition, using a fungicide with proven performance, such as Prosaro® fungicide, can help growers manage FHB. With two very effective active ingredients, Prosaro fungicide provides excellent control of FHB, as well as other stem and leaf diseases.

Al Eadie, fungicide product manager at Bayer, stressed the importance of timing for a fungicide application.

“Fungicides like Prosaro should be sprayed early in the flowering stage to prevent disease from occurring in the plant,” said Eadie. “If weather interferes with ground applications, make an aerial application to limit crop damage, especially when disease risk is high. The window for application lasts about 7-10 days.”

Obtaining 100 percent control for vomitoxin in your crop is not a realistic expectation. However, there are other useful tools and best practices available to growers that limit damage, such as using FHB risk predictors like those provided by the US Wheat & Barley Scab Initiative.2

Harvest: A Deciding Factor

Harvest time is just as important as planning for a strong growing season. Wiersma recommends that growers pay attention to controllable factors during harvest to ensure quality grain shipments.

“You can do some pretty simple things during harvest to limit discounts at the elevator,” said Wiersma. “To eliminate some foreign material and dockage, growers can turn up their blower speed to expel plant material, broken and light grains, and weed seeds.”

In addition, running the combine slower can help maintain kernel quality. More importantly, Wiersma says that a timely harvest will drastically impact grain quality.

“Managing wheat really depends on a variety of factors. Right now, we don’t have a cookbook to tell growers what to do each year,” said Wiersma. “Growers need to focus on producing the best wheat possible based on the lowest price per bushel, not lowest price per acre. If an input improves bushels or protects quality, then it should be considered.”

Yet, the best strategy for limiting losses from dockage and foreign materials is still a preventative one, meaning effective fungicide applications that keep fungal disease at bay to protect grain quality and strong herbicide programs that eliminate weed pressure for season-long control.

Have a grain quality story about wheat to share? Tweet us - @Bayer4CropsUS.

For more information about grain quality in wheat visit www.CropScience.Bayer.us, call 1-866-99-BAYER (1-866-992-21937) or talk with your local sales representative.

©2019 Bayer Group. Always read and follow label instructions. Bayer (reg’d), the Bayer Cross (reg’d), Huskie®, LuxxurTM, Prosaro® and Roundup® are trademarks of Bayer Group. Huskie® Complete is a Restricted Use Pesticide. Not all products are registered in all states. For additional product information, call toll-free 1-866-99-BAYER (1-866-992-2937) or visit our website at www.CropScience.Bayer.us. Bayer CropScience LP, 800 North Lindbergh Blvd. St. Louis, MO 63167.

Sources:

- McMullen, M., Zhong, S., Neate, S. “Fusarium Head Blight (Scab) of Small Grains.” North Dakota State University Extension Service, 2008. https://scabusa.org/pdfs/NDSU_PP-804_FHB-Small-Grains.pdf

- US Wheat and Barley Scab Initiative, 2019.