Proper Planning for Potato Planting

March 26, 2023

It’s been said that “proper planning prevents poor performance.” For potato producers, this adage holds especially true. Before planting a single spud, growers need to consider many variables that span across growing seasons.

“You can’t just say, ‘This year, we’re going to plant potatoes,’” says Kelly Luff, principal scientist for Bayer Crop Science working across the Snake River Plain in southern Idaho. “A grower needs to be looking forward at least three years before he actually plants the crop.”

Crop rotation is crucial to avoiding pitfalls in potatoes. At a minimum, growers should establish a three-year rotation, Luff says. Lengthening the rotation helps to minimize pest and disease pressures within an individual field.

“Growing potatoes back-to-back is not a good practice, nor is it a sustainable practice,” Luff adds. “Knowing the history of a field is critical to having a good pest management program. The previous year’s crop will determine what control methods are needed.”

In southern Idaho, it’s common for growers to rotate a field from potatoes to sugar beets to a cereal crop such as wheat or barley before returning to potatoes, says Jeff Miller, president and CEO of Miller Research based in Rupert, Idaho.

Potato growers in Idaho’s Treasure Valley region, which is known for seed production, have many options for rotation, including onions, mint, carrots, radishes, mustard and oregano, to name a few.

“There may also be corn in the rotation, and occasionally, growers may put a field in alfalfa for five or six years,” Miller adds.

Saad Hafez, an extension nematologist at the University of Idaho, cautions against rotating from alfalfa directly into potatoes. Alfalfa is a potential host for northern root-knot nematode, which can damage tubers and make them unsellable. Adding wheat or another cereal crop in the rotation between alfalfa and potatoes can help alleviate potential issues.

Other nematode species also can wreak havoc in potato fields. The stubby-root nematode is a vector for the tobacco rattle virus, which causes corky ringspot disease in potatoes. The root-lesion nematode can interact with the fungus, Verticillium dahliae, causing verticillium wilt, also known as potato early die.

“Regardless of what crop came before, growers should always sample for nematodes,” Hafez says. “We usually recommend sampling in the fall before planting potatoes in the spring. The nematode population will be higher at that time of year, and if you have an issue, you have time to do some management such as fumigation.”

Soil sampling shouldn’t end with nematodes. Fertility also must be determined.

“The potato crop is very fertility dependent, so consequently, you need to know soil levels of residual nitrogen, phosphorus and potassium,” Luff says, noting that in addition to common macronutrients, some fields may be deficient in micronutrients — including manganese, boron, zinc and copper — that are essential for potato production. “With sampling, you can determine what you need for optimum fertility the coming year.”

Once growers have optimized field conditions for potato production, they should avoid introducing any new problems. Sanitizing equipment is essential, as nematodes can be introduced inadvertently in soil clinging to machinery. Before moving from one field to the next, equipment should be power washed. If a field has a history of harboring nematodes, Hafez recommends working that field last to avoid any cross-contamination.

Planting only potato seed that is certified by an entity such as the Idaho Crop Improvement Association also can help keep fields free of both nematodes and disease.

“The seed really establishes the type of crop you’re going to have,” Miller says. “Most growers will develop a relationship with their seed growers. They know the grower and probably have visited the farm and seen the seed crop.”

Protecting the seed and allowing the potato crop to establish itself without pressure from pests or diseases is important, Luff says.

“The first 75 days of production are crucial,” he says. “If you can control pests that occur within that period of time, it makes growing that crop much easier. If you don’t, then you’ll be fighting those issues all season.”

Luff recommends applying a seed piece treatment to manage soil-borne diseases such as fusarium tuber rot and rhizoctonia while promoting early crop establishment. Emesto® Silver, available from Bayer, is one such product containing both penflufen, a Group 7 fungicide, and prothioconazole, a Group 3 fungicide.

At planting, an in-furrow application of fluopyram, another Group 7 fungicide, will help manage early-season nematodes, early blight and white mold. These products include Velum® Prime and Velum® Rise from Bayer.

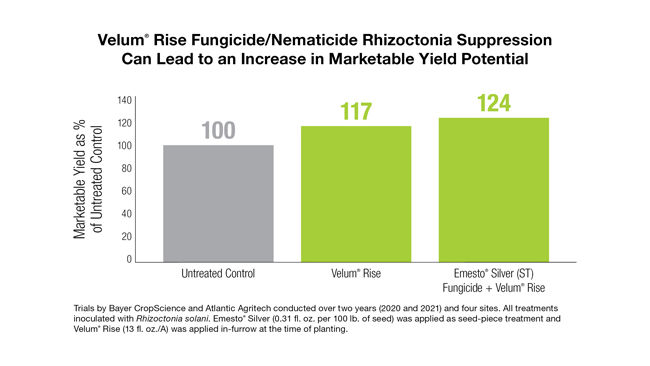

Velum Rise is the newest addition to the Velum family built to defend against key soil-borne diseases like Rhizoctonia and black dot. The fungicide/nematicide features both penflufen and fluopyram and is applied in-furrow to help start your season on the rise.

Trial data has shown that using Velum Rise with Emesto Silver seed treatment can increase marketable yield by 15% when compared to not-inoculated control. Learn more on how to start your season on the rise with Velum Rise here.

“Couple that with a really strong insecticide that offers longer residual control than any other material on the market. That would be Admire® Pro,” says Luff, referring to Bayer’s product containing imidacloprid, a Group 4A insecticide. “It provides good control for aphids, Colorado potato beetles, leafhoppers and some suppressive activity on psyllids as well.”

While growers will be concerned with costs versus benefits, Luff says that a comprehensive early-season program will lead to healthier plants that ultimately will be able to withstand other challenges later in the year.

“If you get the first part of the season right, it saves input costs on the other end,” Luff adds. “You’re not fighting something you messed up earlier in the season.”

Learn how the Bayer PLUS eligible products within the 75-Day IPM program from Bayer is a force in at-plant solutions.