5 MIN READ

Corn Yield Potential and Row Spacing

May 3, 2022

Background

Prior to mechanization, row spacing was determined by the amount of space needed for farm animals to pull equipment between rows. As tractors took over horsepower, researchers explored the adoption of narrower rows. In the 1960’s and 1970’s researchers determined potential yield increases of 5 to 7% by switching from 40-inch to 30-inch corn rows.1 Decades of research since then have determined geography and corn products can affect yield results as row spacing becomes narrower than 30-inches.

Yield Components

Narrowing rows results in more equidistant plant spacing within the row with the same seeding rate. More space for individual plants is theorized to reduce competition for water, nutrients, and light.2 Corn plants grown in narrow rows have shown increased yield potential in substantial, yield-limiting environments. While moisture evaporation from the soil surface is reduced with full canopies, transpiration increases with more leaf area exposed to sunlight (as a result of more equidistant spacing). Ear size and ear number are balanced by corn plants in relation to plant population and spacing.

Equipment Considerations

Compaction is a concern with narrowing row spacing. Minimizing wheel traffic may make a difference in yield comparisons between narrow and wider rows. Driving on planted rows and creating long-term compaction may result in the loss of potential yield gains from switching to narrower rows.3

Equipment costs cannot be discounted when figuring economic returns of switching from wider to narrow row spacings. A yield advantage of 6 to 8% over 7 to 10 years is the estimated yield increase needed on larger acreage (greater than 500 acres) to recoup the costs of switching equipment.4 Northern Corn Belt geographies are likely to experience a yield increase from narrower rows consistently over the years.1,2,3,5 Additional considerations for equipment:

- Planting. Equipment used for two crops (soybean and corn) has been a motivating factor for many farmers adopting narrow row corn. A need for new equipment for either narrow row crop would lower or negate the requirement for yield increases to make a potential return on investment.

- Weed Control. Cultivators will likely be limited to 30-inch row spacing. Corn is less adapted to recover from tire damage, and narrow tires are needed for pesticide and fertilizer equipment.

- Harvesting. Corn headers may need to be replaced with one heavier for its size. Harvest has been reported as more tiring with narrow row fields. As an unforeseen bonus, deer damage may be limited to field perimeters.

- Twin-Row Configuration. Fields with populations of 34,848 plants/acre can have plants staged farther apart when seeded in a “diamond pattern”. When plants are 6 inches apart in 30-inch rows, plants would be 9.6 inches away from their nearest neighbor across a 7.5-inch twin row (Figure 1).5 A new corn head is not necessary as the two paired rows are gathered into the same row unit at harvest.

Seeding Management

Population and Corn Stand. Studies have shown increased plant populations can be achieved with or without narrowing row spacing. Increasing seeding rate to help reduce weed competition from early canopy completion can oftentimes increase yield potential.5 Economically optimal corn plant populations are similar among row widths.2,6

Available tools can help increase performance and profit potential by generating optimal planting population recommendations. Recommendations made with the Population Optimizer found at are powered by years of planting population testing data. Use these recommendations and work with a local DEKALB® brand dealer to maximize the potential of DEKALB® corn.

Corn Product Selection. Shorter-statured, earlier-maturing corn products with fewer or narrower leaves have been thought to respond positively to narrow rows combined with higher plant populations.2,3 As such, Northern Corn Belt researchers are finding narrow row corn to have a positive yield response in their shorter growing seasons. Taller, later-maturing corn products with more leaf area may be better-suited for wider row spacing.5 Silage corn products have also shown a forage dry matter yield increase of 4 to 7% with 20-inch rows compared to 30-inch row spacing.7 This increase was affected by relative maturity of the silage product.

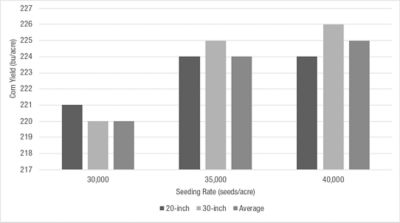

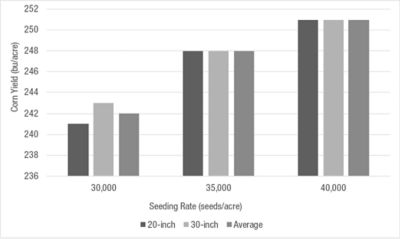

Stalk breakage or standability is a concern for some farmers with increases in population; however, corn products can be selected for end of season standability and stalk strength to help mitigate these concerns. Typically, new corn products can withstand the higher plant density. Researchers at Bayer conduct numerous trials to explore performance of corn products under different management and inputs. Figures 2 and 3 below show the yield differences between two years of row spacing and population data. Figure 4 shows single-year results from a twin-row and corn plant population study.

Conclusion

Potential yield increases due to narrow row spacing are higher and more consistent in the Northern Corn Belt. Farmers should recognize the potential year-to-year variability of yield response to narrow rows in the Central Corn Belt and Southern regions. Farmers should recognize the potential year-to-year variability of yield response to narrow rows in the Central Corn Belt and Southern regions. Corn product selection and optimal plant population are very important decisions regardless of row spacing. Additional considerations when adopting narrow row spacing are equipment consolidation, cost of new or modified equipment, and changes to management practices.

Sources:

1 Nielsen, R.L. 1997. Perspectives on narrow row spacings for corn (less than 30 inches). Purdue University. AGRY-96-17.

2 Stahl, L., Coulter, J., and Bau, D. 2021. Narrow-row corn production in Minnesota. University of Minnesota Extension.

3 Brunoehler, R. 2001. On-farm tests back narrow rows. Corn+Soybean Digest. https://www.farmprogress.com/farm-tests-back-narrow-rows.

4 Bitzer, M. Herbek, J., et al. A comprehensive guide to corn management in Kentucky. University of Kentucky Multidisciplinary Extension Team. ID-139.

5 [Online] Illinois Agronomy Handbook. Pgs. 20-22. http://extension.cropsciences.illinois.edu/.

6 Wright, E. and Licht, M. 2018. Corn row spacing considerations. Iowa State University Extension and Outreach.

7 Pieper, M.A. 2018. Silage corn hybrid response to row width and plant density in the intermountain west. Utah State University. All Graduate Theses and Dissertations. 7082.

1210_13851