10 MIN READ

Row Configurations in Cotton Production

January 15, 2020

TRIAL OBJECTIVE

- U.S. cotton is currently planted on a wide variety of row configurations. Recently, interest has emerged in wider row spacings ranging from 60- to 78-inch rows.

- Wider spacing can help standardize equipment across grain crops and cotton and could have other agronomic advantages.

- This trial was conducted to evaluate wider row spacings for cotton agronomic management considerations including boll rot potential, growth control, and overall yield potential.

RESEARCH SITE DETAILS

| Location | Scott, MS |

| Soil Type | Commerce silt loam |

| Previous Crop |

Corn |

| Tillage Type |

Conventional |

| Planting Date | 05/30/19 |

| Harvest Date | 10/22/2019 |

| Potential Yield (bu/acre) |

2000 |

| Seeding Rate (seeds/acre) |

30K, 40K, 50K |

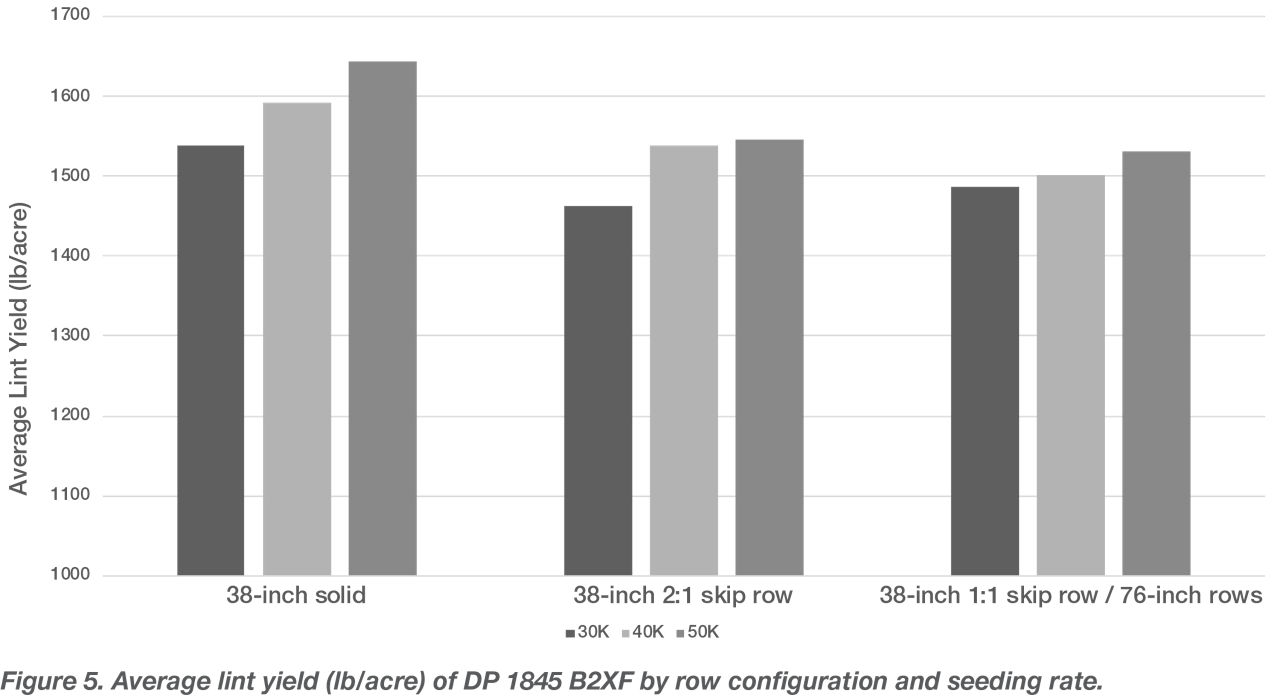

Two Deltapine® cotton varieties, DP 1646 B2XF and DP 1845 B3XF, were planted in three different row configurations: solid planted 38-inch rows, 38-inch 2:1 skip row, and 38-inch 1:1 skip row (equivalent to 76-inch solid row spacing).

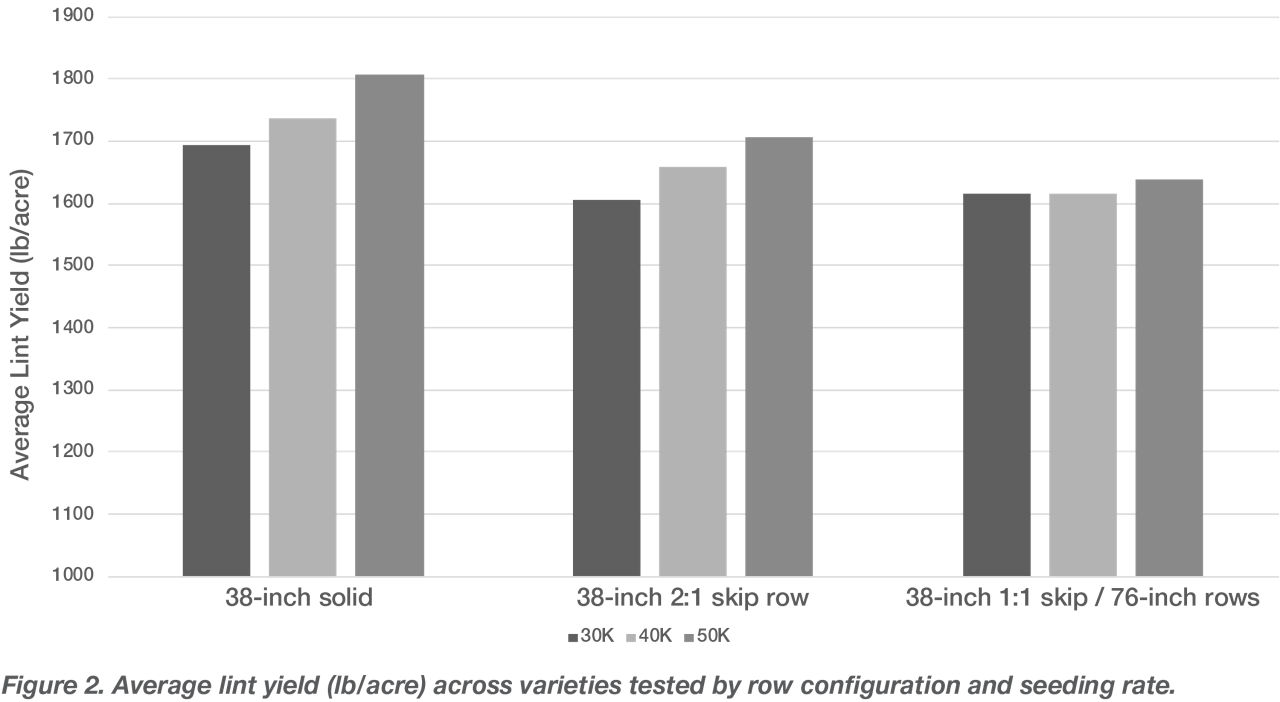

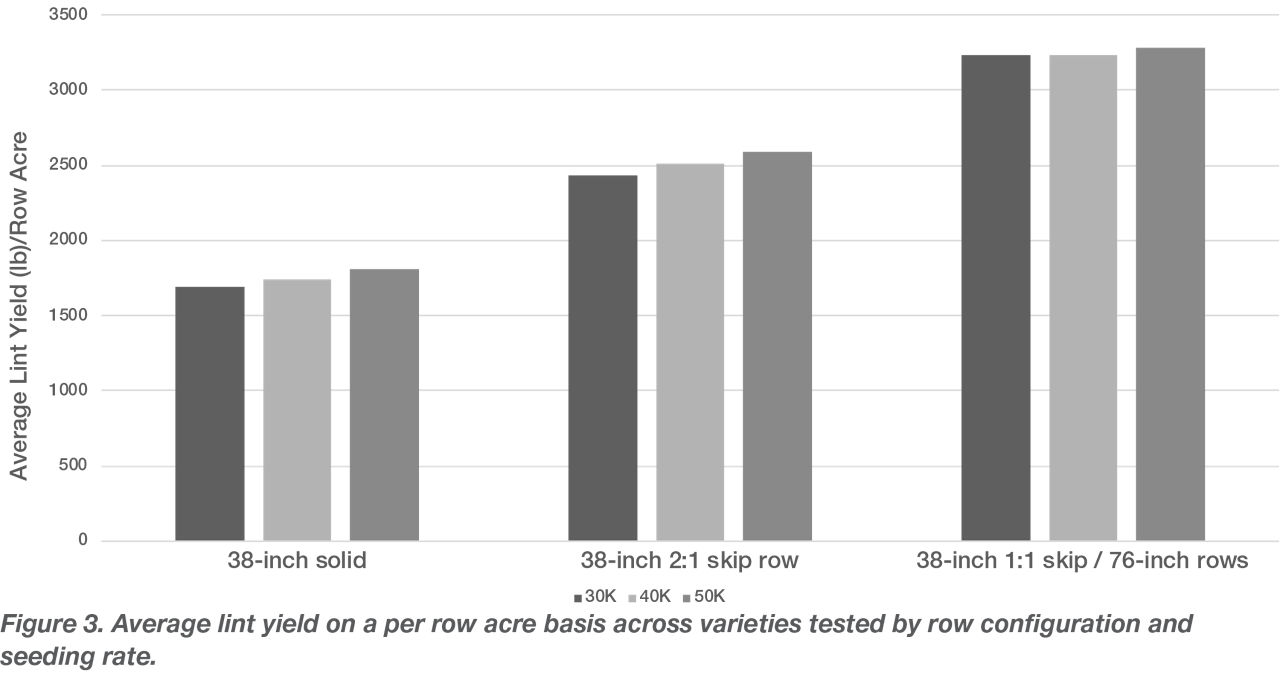

Average yield across both cotton varieties was considered on a per acre basis and on a per row acre basis. Per row acre does not include the land area of the skipped rows and was used to demonstrate the yield potential of the plants (Figure 3).

All treatments received 90 lb of liquid UAN (32% N).

Mepiquat chloride (4.2%) plant growth regulator (PGR) was applied as needed across all treatments. Growing conditions for the 2019 season did not require aggressive PGR applications for cotton at the Scott Learning Center. A total of 38 fl oz/acre were applied (10 fl oz/acre on July 14, 12 fl oz/acre on August 7, and 16 fl oz/acre on August 30).

All weed control, insect control, and irrigation inputs were applied per local standards on all treatments.

The trial was planted in 12-row strips, 250 feet long, and 6 rows were harvested for yield.

Turnouts from a separate yield trial at the Scott Learning Center were used to adjust final yield from seed cotton per acre to lint yield per acre.

UNDERSTANDING THE RESULTS

- Very high yields were observed in this demonstration compared to historical yields at the Scott Learning Center.

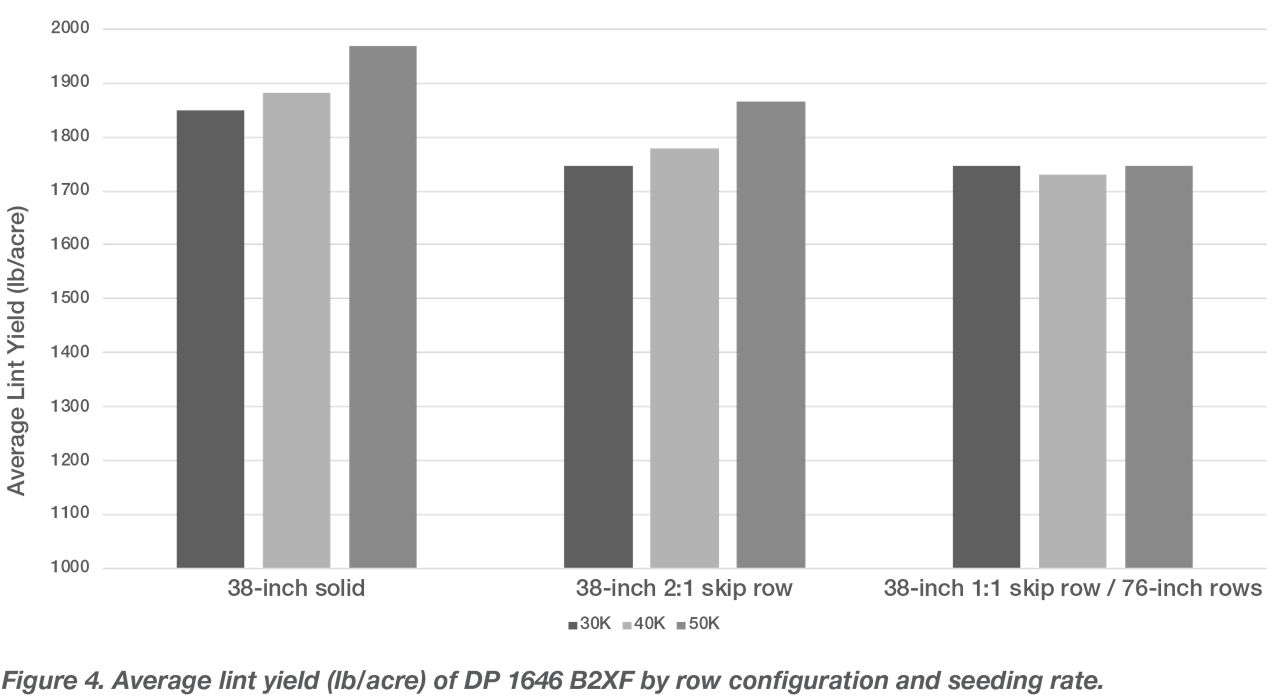

- All tested row configurations in this demonstration had competitive yield potential, with the 38-inch solid planted configuration having the numerically highest yield.

- Variety selection did not appear to be a substantial interacting factor on the success of the planting systems.

- The yield per row acre data suggest that cotton plants have tremendous ability to compensate for both a range of planted population and unplanted areas, which are intentionally introduced into the skip row systems.

- The highest “down the row” yield observed in the study was 3277 lb lint/acre – 6.8 bales/acre. This is an indication of the yield potential that cotton plants have given favorable weather and sound agronomic management.

- 2019 did not offer an opportunity to evaluate boll rot potential in skip row plantings but past work at the Scott Learning Center suggests that boll rot is often reduced in skip row plantings. Shade induced shedding events are typically reduced also.

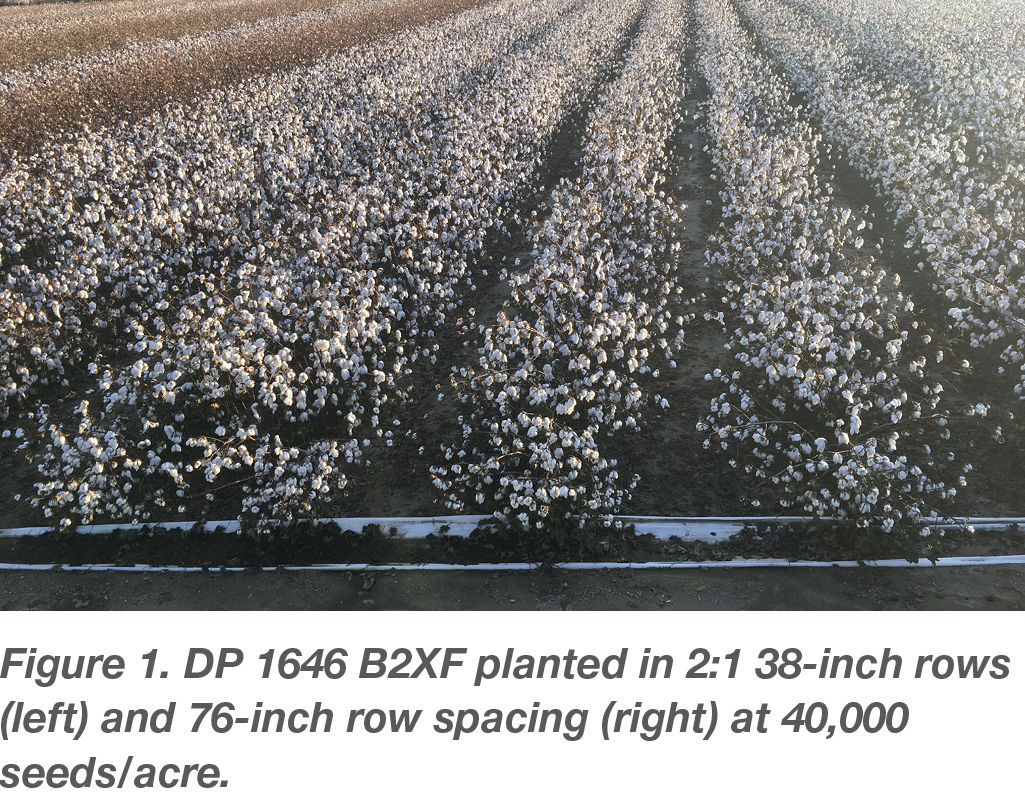

- For this demonstration, vegetative growth potential was observed to be higher and easier to manage in the skip row systems. This may be due to less plant-to-plant competition for light between the rows, allowing plants to grow out instead of up (Figure 1). This can lead to both increased levels of fruit retention and faster fruit accumulation and plants to be more responsive to PGR application. This is a primary driver in the adoption of skip row plantings and agrees with past results.

KEY LEARNINGS

- All tested treatments (both variety and row patterns) had competitive yield potential compared to standard systems commonly used in commercial cotton production in the Midsouth.

- In cases where needs arise, skip row systems could offer the ability to maintain yield potential while allowing a standardization in equipment, reductions in fruit shedding/boll rot1, and opportunities to better manage vegetative growth.

- There are several factors to consider when evaluating the suitability of a skip row or wide row spacing system. Factors to consider include:

- Historical growth potential of the field. Fields that are typically too tall at the end of the season can be good candidates for skip row planting patterns.

- Variety selection. Generally, more aggressive or growthy type plants may benefit from skip row plantings in this area.

- For this area, plant populations in the range tested here, 30,000-40,000 plants/acre, are recommended.

- PGRs should be used as dictated by past knowledge of the field and plant monitoring in the field during the growth season regardless of row configuration.

- This demonstration applied a 38/76-inch row system due to equipment availability. A 30/60-inch system is a potential option for skip row and these results could likely translate into a 30/60-inch row system. Growers should carefully consider row spacing options prior to changing the production system on their farm.

Source:

1 Newman, M.A. 2011. Cotton disease and nematode control. The University of Tennessee Extension. E&PP INFO24. https://ag.tennessee.edu/EPP/Redbook/10cotton%20disease%20and%20nematode%20control%20MAYBE%20REPLACE.pdf.

3014_R1