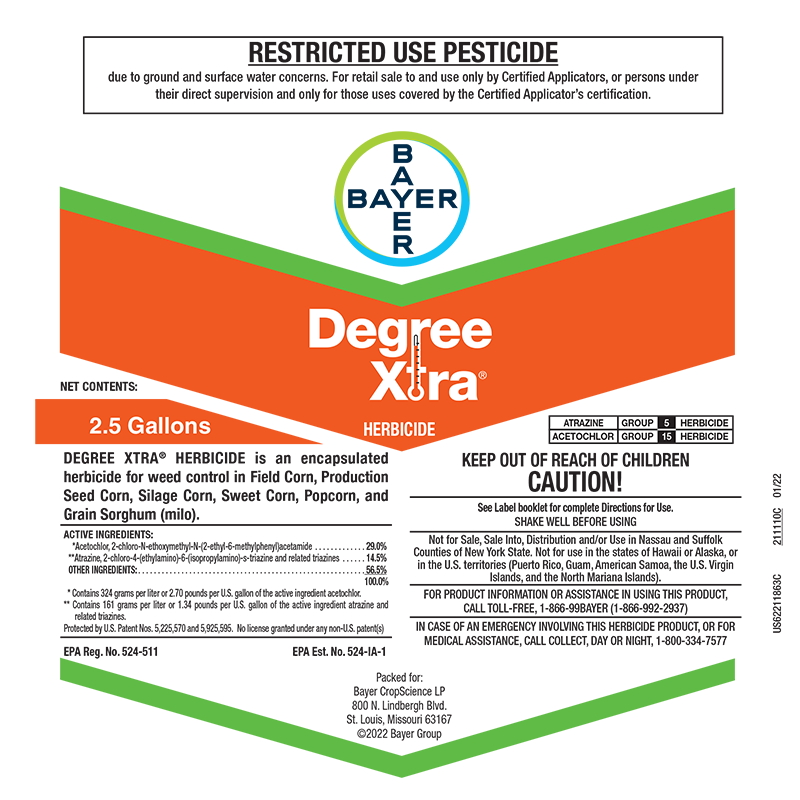

Degree Xtra Herbicide

HerbicideDegree Xtra® herbicide is a premix that contains acetochlor and atrazine. As soil temperatures rise, the patented micro-encapsulation technology in Degree Xtra delivers an immediate dose of atrazine with a slow release of acetochlor for just the right amount of weed control. The process allows for increased crop safety and longer-lasting residual control of a wide range of key grass and broadleaf weeds.

Approved In

AL, AR, CO, CT, DC, DE, GA, IA, ID, IL, IN, KS, KY, LA, MD, MI, MN, MO, MS, MT, NC, ND, NE, NJ, NM, NV, NY, OH, OK, OR, PA, RI, SC, SD, TN, TX, UT, VA, VT, WI, WV, WY

Labels / Safety Data Sheets (MSDS)

DEGREE XTRA HERBICIDE Label

DEGREE XTRA HERBICIDE MSDS - English

DEGREE XTRA HERBICIDE MSDS - Spanish

Effective Against

Our portfolio has products to fight a variety of weeds, pests and diseases.

Barnyard Grass

Cocklebur

Common Ragweed

Common Waterhemp

Foxtail Species

Lambsquarters

Registered Crops

Our products are available for use on a variety of different crops.

checkcorn field

checkcorn production seed

checkcorn sweet

checkgrain sorghum

checkpopcorn

checksilage corn