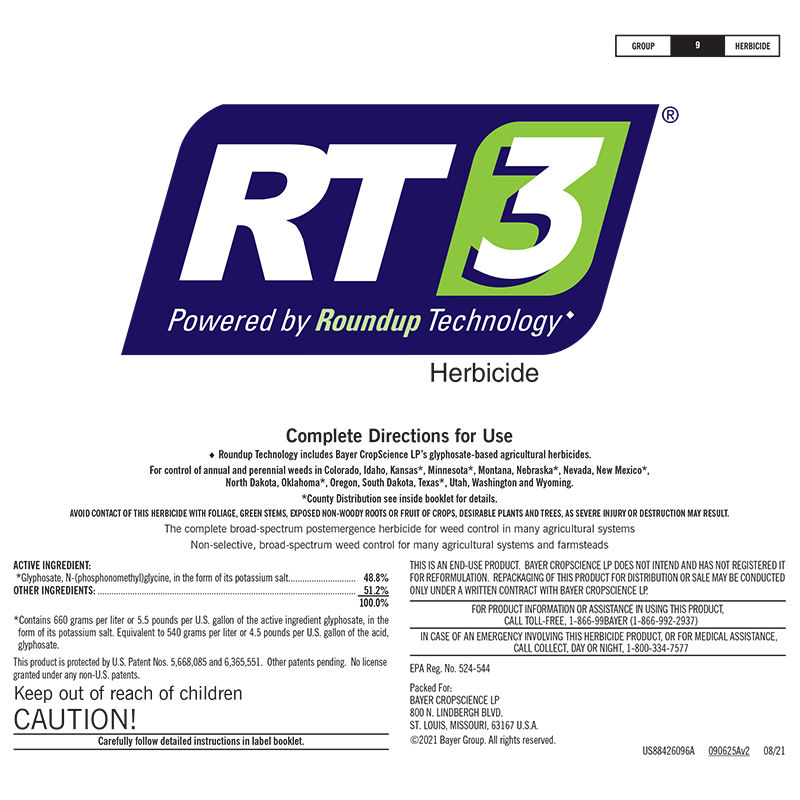

RT 3 Herbicide

HerbicideRT 3® herbicide contains up to 50 percent higher glyphosate concentration than most generics to control more acres per gallon. RT 3 herbicide has shown reliable, consistent performance on tough-to-control weeds, such as non-glyphosate resistant Russian thistle and kochia.

Approved In

CO, IA, ID, KS, MN, MT, ND, NE, NM, NV, OK, OR, SD, TX, UT, WA, WY

Labels / Safety Data Sheets (MSDS)

RT 3 HERBICIDE Label

RT 3 HERBICIDE MSDS - Spanish

RT 3 HERBICIDE MSDS - English

Effective Against

Our portfolio has products to fight a variety of weeds, pests and diseases.

Cheatgrass

Kochia

Marestail

Russian Thistle

Volunteer Wheat

Registered Crops

Our products are available for use on a variety of different crops.

checkcorn field

checkcorn production seed

checkcorn sweet

checkgrain sorghum

checkpopcorn

checksilage corn